In modern materials and manufacturing, UV light curing of resin has revolutionized production. As a leading manufacturer of UV curing light for resin and Electronic UV Lamp Power Supplies, Fiver Electronic Technology presents this comprehensive guide exploring how UV light for resin cures, the various resin types, the crucial role of UV resin curing lamps, and their diverse applications.

1. How UV Light Cures Resin: The Science of Photoinitiated Polymerization

UV curing of resin relies on photoinitiated polymerization. When UV light for resin strikes the material, photoinitiators absorb photon energy and become excited. These excited photoinitiators generate reactive species (free radicals or cations), initiating a chain reaction causing monomers and oligomers to polymerize and crosslink, transforming liquid resin into a solid polymer in seconds. This precise, rapid process creates strong chemical bonds, resulting in cured resins with excellent mechanical properties.

2. Diverse Types of UV-Curable Resins

A wide range of resins are compatible with UV curing:

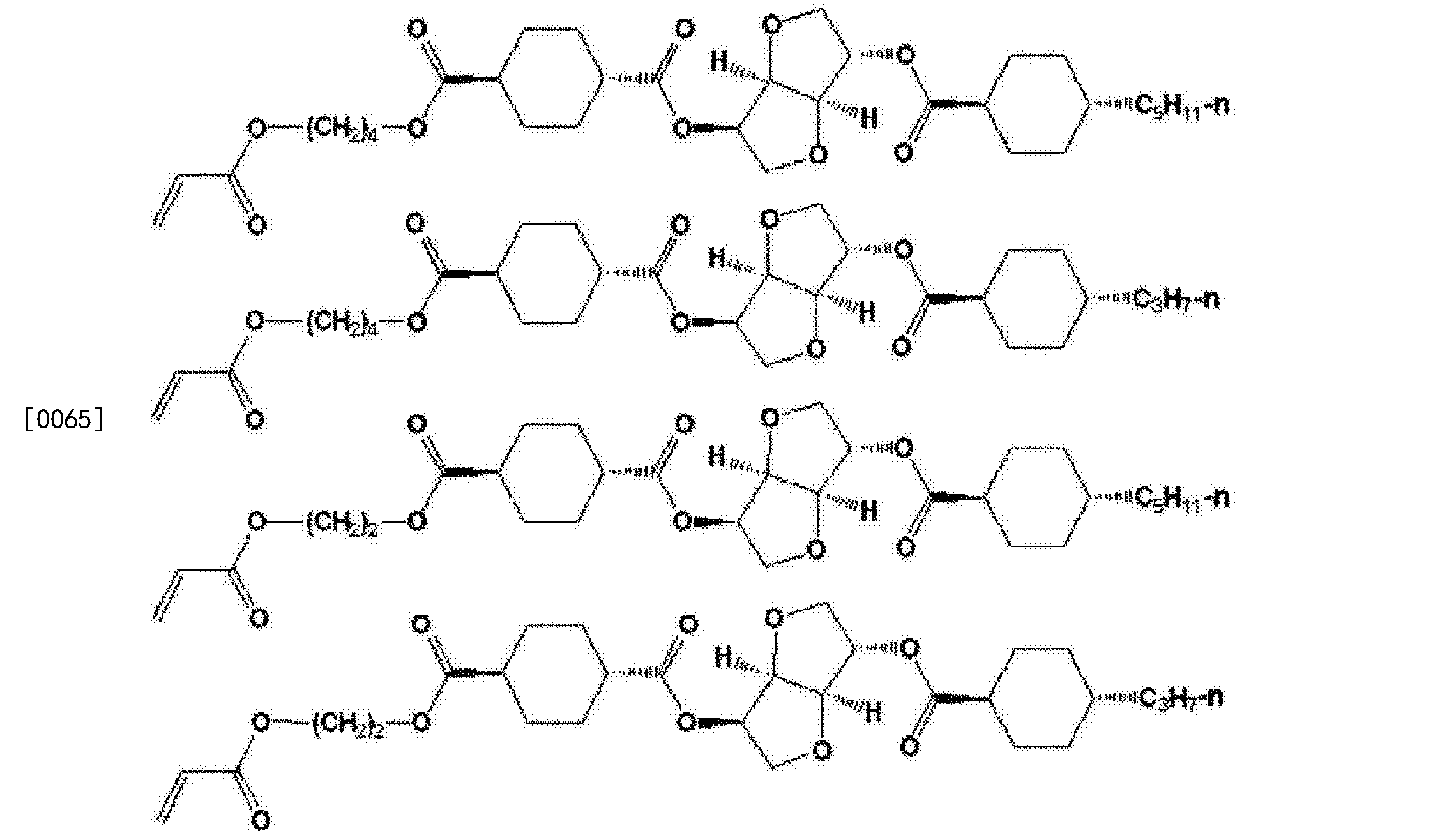

Acrylate Resins:

Polyurethane Acrylate (PUA): Combines flexibility and wear resistance, ideal for coatings and adhesives.

Epoxy Acrylate (EA): Offers high hardness and adhesion, suitable for electronic packaging and high-precision 3D printing.

Polyester Acrylate (PEA): Provides flexibility and cost-effectiveness, commonly used in coatings and adhesives.

Epoxy Resins: Cationic photo-curable epoxies offer low shrinkage and excellent adhesion, ideal for precision electronics. UV light for curing epoxy is often used with these resins.

Silicone Resins: Exhibit outstanding heat and weather resistance, suitable for high-temperature coatings and outdoor applications.

Unsaturated Polyester Resins: Offer fast curing and affordability, used in furniture manufacturing and handicrafts.

3. The Crucial Role of UV Curing Lamps (Manufactured by Fiver Electronic Technology)

The UV resin curing lamp is essential for effective curing. Wavelength and intensity are critical. Matching the lamp's output to the photoinitiator's absorption spectrum is crucial. For instance, resins with photoinitiators absorbing at 365nm require a UV curing light for resin emitting at or near that wavelength. Fiver Electronic Technology manufactures a range of UV curing light for resin to suit various needs, including specialized UV curing lamp 3D printer models.

Intensity directly impacts curing speed. Higher intensity accelerates polymerization but requires careful calibration to prevent overheating. Uniform light distribution, a key feature of Fiver's UV curing light for resin, ensures consistent curing across the surface, especially vital for electronics and optical components. Light cured resin achieves its properties through this process.

We at Fiver Electronic Technology also manufacture Electronic UV Lamp Power Supply for stable and reliable power to the lamps. Using the right UV cure resin with our lamps and power supplies provides optimal results.

| Parameter Range of UV Curing Lamps From Fiver | |

| Power output | 500w to 40kw |

| Wavelength | 320nm to 450nm |

| Arc length | 50mm to 2000mm |

| Tube diameter | 18mm to 32mm |

| Power density | 30/60/80/120/160/200 w/cm |

| Spectrum | UVA / UVB / UVC / UVV |

| Filler | Mercury / Metal halide / Gallium iodide |

| Material | US General Electric, Raesch Quartz Germany |

| End caps | Ceramic / metal ( more than 100 kinds) |

| Service life | 800 to 1000 hou |

Contact us to customize your uv lamp for curing resin jerry@fiveruvc.com

4. Wide-Ranging Applications of UV-Cured Resin

UV-cured resins have diverse applications:

3D Printing: Enables rapid creation of highly detailed models. Using a dedicated UV curing lamp 3D printer configuration allows for efficient and precise curing of light cured resin.

Coatings and Inks: Provides durable, scratch-resistant, and chemically resistant finishes for various products.

Electronics: Ensures reliable electrical connections and protection for sensitive components in PCBs and encapsulation.

Dental: Offers natural-looking and durable restorations.

Optics: Used in manufacturing lenses, fiber coatings, and optical films due to high transparency.

Emerging Fields: Potential in self-healing coatings and advanced 3D printing at micro and nano-scales. Many of these applications use uv cure epoxy.

Fiver Electronic Technology: Your Partner in UV Curing Solutions

As a leading manufacturer of UV curing light for resin and Electronic UV Power Supply, Fiver Electronic Technology provides high-quality, reliable solutions for diverse resin curing applications. Using the right UV cure resin and our equipment is essential for optimal results. Contact us to learn more about how our products can optimize your processes.

Post time:2025-01-07