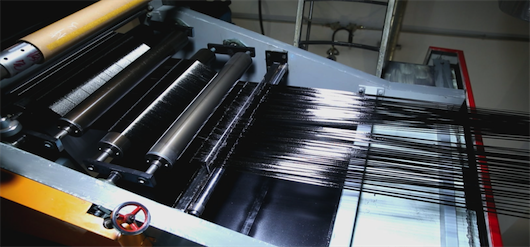

In composite manufacturing, achieving consistent quality and maximizing production efficiency in winding processes hinges on the right curing equipment for winding products. Fiver Electronic Technology, a leading UV lamp manufacturer, provides state-of-the-art, customizable UV curing lamps and electronic power supplies designed to meet the unique demands of modern filament winding.

Custom-Engineered UV Curing for Optimal Results:

We understand that every filament winding application is different. That's why we don't offer a one-size-fits-all solution for your curing equipment for winding products. Our expertise lies in custom-engineering UV curing lamps to perfectly match your specific requirements, optimizing B-stage, complete, and gel coat curing for superior filament wound composites.

Tailored B-Stage Curing for Enhanced Winding Dynamics:

For B-stage curing (partial curing), we customize lamp placement after the resin bath and before winding, precisely controlling UV output to achieve the ideal tacky state. This tailored approach to curing equipment for winding products offers several advantages:

Increased Winding Speed: Optimized tackiness improves resin adhesion, allowing for faster winding at larger approach angles.

Consistent Wall Thickness: Enhanced resin retention ensures consistent part wall thickness.

Reduced Waste: Minimizes resin dripping, reducing material waste and cleanup.

Customizable Complete Curing for Maximum Durability:

For complete curing, we configure our UV curing lamps to be positioned above and/or below the rovings immediately after the resin bath, ensuring complete fiber coverage, particularly for fiberglass. This is a key feature in effective curing equipment for winding products. We also offer customizable configurations for simultaneous curing during winding and post-winding final curing for parts that have undergone UV B-stage curing. This tailored approach guarantees the highest quality and durability of finished filament wound composite parts.

Custom Gel Coat Curing for Flawless Finishes:

Our UV curing lamps offer a customizable solution for gel coat curing, providing a scratch-resistant and durable topcoat for filament wound parts like cylinders and golf shafts. Choosing the right curing equipment for winding products is crucial for this process. Working with your specific gel coat formulation, we ensure smooth, even curing on rotating mandrels, resulting in a flawless, high-quality finish and long-lasting protection.

Intelligent, Customizable Electronic UV Power Supplies:

Our UV lamp power supply are the core of our customizable UV curing systems, delivering stable and reliable power to the lamps. These power supplies, an integral part of our curing equipment for winding products, use advanced technology allowing for precise control of UV output, enabling customized curing profiles tailored to different winding products. This level of control ensures consistent and repeatable results, batch after batch.

Your Partner in Customized UV Curing Solutions:

At Fiver Electronic Technology, we are committed to providing tailored UV curing solutions that meet your exact needs for curing equipment for winding products. Our UV curing lamps and power supplies are designed with built-in safety mechanisms and are easily integrated into existing or new winding production lines. This customized approach minimizes disruption and maximizes ROI.

Optimize Your Winding Production with Custom Fiver UV Curing:

If you're seeking custom-engineered curing equipment for winding products, Fiver Electronic Technology offers the perfect combination of innovation, reliability, and performance. Our tailored UV curing solutions enhance production efficiency, reduce waste, improve product quality, and create a safer working environment. Contact us today to discuss your specific requirements and discover how our customized solutions can optimize your filament wound composite part production.

Post time:2025-01-06