Introduction

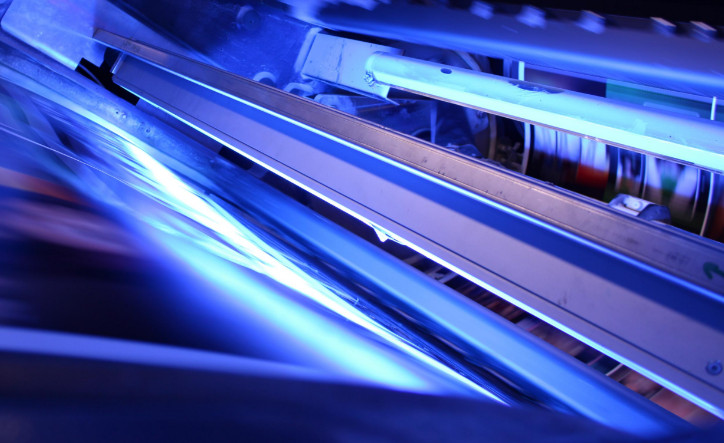

What is UV curing? This innovative process harnesses ultraviolet light to transform liquid materials into hardened finishes in seconds. Whether you’re new to UV curing technology or a seasoned professional, this guide unpacks everything from the science behind ultraviolet curing to practical tips for optimizing your UV curing systems.

What is UV Curing?

UV curing is a rapid, energy-efficient method that uses UV radiation to instantly cure inks, coatings, adhesives, and other UV-curable materials. Unlike traditional drying processes that rely on heat or evaporation, UV curing triggers a photochemical reaction called polymerization, creating durable, high-quality finishes.

How Does UV Curing Work? The Science Simplified

At the heart of the UV curing process are photoinitiators—light-sensitive compounds embedded in the material. When exposed to specific UV wavelengths, these molecules activate, sparking a crosslinking chain reaction that bonds materials at the molecular level. This reaction delivers precise, consistent results ideal for industries like printing, packaging, and electronics.

Top Benefits of UV Curing Technology

Why choose UV curing equipment over traditional methods?

Speed: Cure materials in seconds, slashing production time.

Efficiency: Lower energy consumption vs. heat-based drying processes.

Versatility: Ideal for UV curing for adhesives, inks, coatings, and plastics.

Quality: Enhanced durability, chemical resistance, and gloss.

Eco-Friendly: Reduced VOC emissions and waste.

Key Components of a UV Curing System

UV Curing Lamps: The UV lamp is the heart of the curing system. Different lamp types, such as mercury vapor, gallium-doped, and metal halide, provide varying spectral peaks and power densities, making them suitable for specific applications

UV Lamp Type | Peak Wavelength | Curable Thickness | Best Applications |

| Mercury Vapor Lamps | 365 nm (UVA) | 100–200 microns | General-purpose curing (inks, coatings, adhesives), printing, wood finishes |

| Metal Halide Lamps | 350–450 nm (UVA) | 50–300 microns | Thick coatings, 3D printing, industrial applications |

| UV LED Lamps | 365–405 nm (UVA) | 10–100 microns | Thin films, electronics, medical devices, eco-friendly setups |

| Gallium-Doped Lamps | 403–417 nm (visible) | 50–250 microns | Clear coatings, deep-cure adhesives, wavelength-sensitive materials |

| Iron-Doped Lamps | 380–390 nm (UVA) | 100–200 microns | Automotive coatings, UV varnishes, high-gloss finishes |

| Excimer Lamps (e.g., XeCl) | 308 nm (UVB/UVC) | 10–50 microns | Ultra-thin films, medical sterilization, high-precision curing |

Irradiators/Reflectors: Focus UV light for maximum efficiency.

UV Curing Ballasts:A critical component for regulating power and ensuring stable lamp performance, Electronic UV Ballasts like Fiver’s 12KW Series elevate industrial curing efficiency. Key features include:

Adjustable High-Voltage Output (1000–2200V): Choose from three models (12KW, 12KWM, 12KWH) to match UV lamp requirements for inks, coatings, or adhesives.

Stable, Flicker-Free Operation: High-frequency output (8kHz–15kHz) ensures uniform curing on fast-moving production lines.

Smart Industrial Design: RS485 Communication: Integrates with PLC systems for automated control of power, temperature, and conveyor speed.

Forced Air Cooling (IP20 Rated): Built for reliability in high-temperature tunnel furnace environments.

Energy Savings: Standby mode reduces idle power by 30%, while a lamp lifespan timer schedules maintenance without downtime.

Safety Gear: Shields, UV-blocking glasses, and gloves to protect against UV radiation.

Pro Tip: For “best UV curing lamps for [specific application]”, consult experts like Fiver Electronic Technology to match your needs.

Choosing the Right UV Curing System

Selecting UV curing equipment depends on factors like material type, industry (e.g., UV curing in printing or automotive), and production speed. Key considerations:

Lamp Type: Match wavelengths to your material’s photoinitiators.

Intensity & Configuration: Ensure even curing for complex shapes.

Scalability: Adaptable systems for future growth.

Common UV Curing Challenges & Solutions

Uneven Curing: Often caused by misaligned reflectors or inconsistent material thickness. Fix: Regular UV curing lamp maintenance and calibrations.

Slow Curing: Check lamp output or photoinitiator compatibility.

Lamp Issues: Replace aging lamps and ensure proper cooling.

UV Curing Safety Precautions

Always use PPE (glasses, gloves) and equipment shielding.

Monitor UV radiation exposure with safety interlocks.

The Future of UV Curing Technology

Advancements in UV curing systems, LED lamps, and eco-friendly materials are driving adoption across industries. From UV curing for packaging to medical device coatings, this technology offers faster, greener solutions.

FAQs: UV Curing Basics

Q: How does UV curing work?

A: UV light activates photoinitiators, triggering polymerization.

Q: What are the advantages of UV curing over solvent-based methods?

A: Faster speeds, lower energy use, and superior finish quality.

Need a UV Curing Partner?

As a leading manufacturer of UV curing lamps and electronic UV ballasts, Fiver Electronic Technology delivers tailored solutions for your industry. Explore our range at www.fiveruvc.com or contact us to discuss UV curing systems optimized for your needs.

Post time:2025-02-07