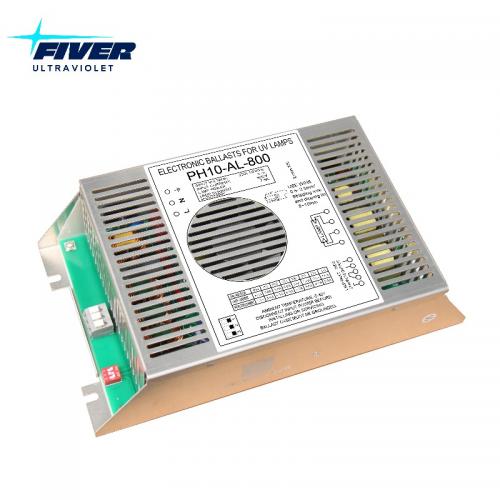

12KW High Voltage Electronic UV Lamp Driver for UV Tunnel Furnace

12KW High Voltage Electronic UV Lamp Driver for UV Tunnel Furnace| Industrial Curing Solution

FIVER 12KW UV Driver: Engineered for UV Tunnel Furnace Efficiency

Looking for a reliable and high-performance 12KW UV ballast? The FIVER 12KW High Voltage Electronic UV Lamp Driver is the ultimate power solution for UV tunnel furnaces, delivering precision, speed, and durability in high-temperature curing applications. This advanced UV driver, also known as a UV ballast and power supply, is built to meet the rigorous demands of industrial production lines. It ensures consistent UV output for coatings, adhesives, and composites, while reducing energy costs and downtime.

Key Features for UV Tunnel Furnace Applications

High-Voltage Output (1000–2200V)

- Adjustable Ranges: Choose 12KW (1000-1300V), 12KWM (1300-1750V), or 12KWH (1750-2200V) models to match UV lamp requirements.

- Max Current: 13A (standard) for intense UV irradiation, accelerating curing cycles in tunnel furnaces. This powerful UV lamp controller ensures optimal performance.

Stable & Flicker-Free Operation

- Output Frequency: 8kHz–15kHz ensures uniform light distribution, critical for even curing across large surfaces.

- Power Vector Control: 0.1kW resolution for precise energy adjustment to material thickness and speed.

Smart Industrial Design

- RS485 Communication: Integrate with PLC systems for automated control of curing parameters (power, temperature, conveyor speed).

- Thermal Management: Forced air cooling (IP20 rated) prevents overheating in high-ambient-temperature tunnel environments.

Energy & Cost Savings

- Standby Mode: Reduces idle power consumption by 30% during production pauses.

- Lamp Timer: Tracks UV lamp lifespan to schedule maintenance without interrupting workflows.

Technical Specifications - UV Digital Power Supply

| Parameter | Specification |

| Input Voltage | 380V AC (±10%), 50/60Hz (480V input boosts output by 20%) |

| Output Range | 1000-1300V (12KW), 1300-1750V (12KWM), 1750-2200V (12KWH) |

| Max Output Current | 13A (12KW), 10A (12KWM), 8A (12KWH) |

| Output Frequency | 8kHz–15kHz |

| Dimensions | 645mm x 375mm x 350mm (wall-mounted) |

| Protection | Overcurrent, short-circuit, phase-loss, overtemperature, and humidity resistance |

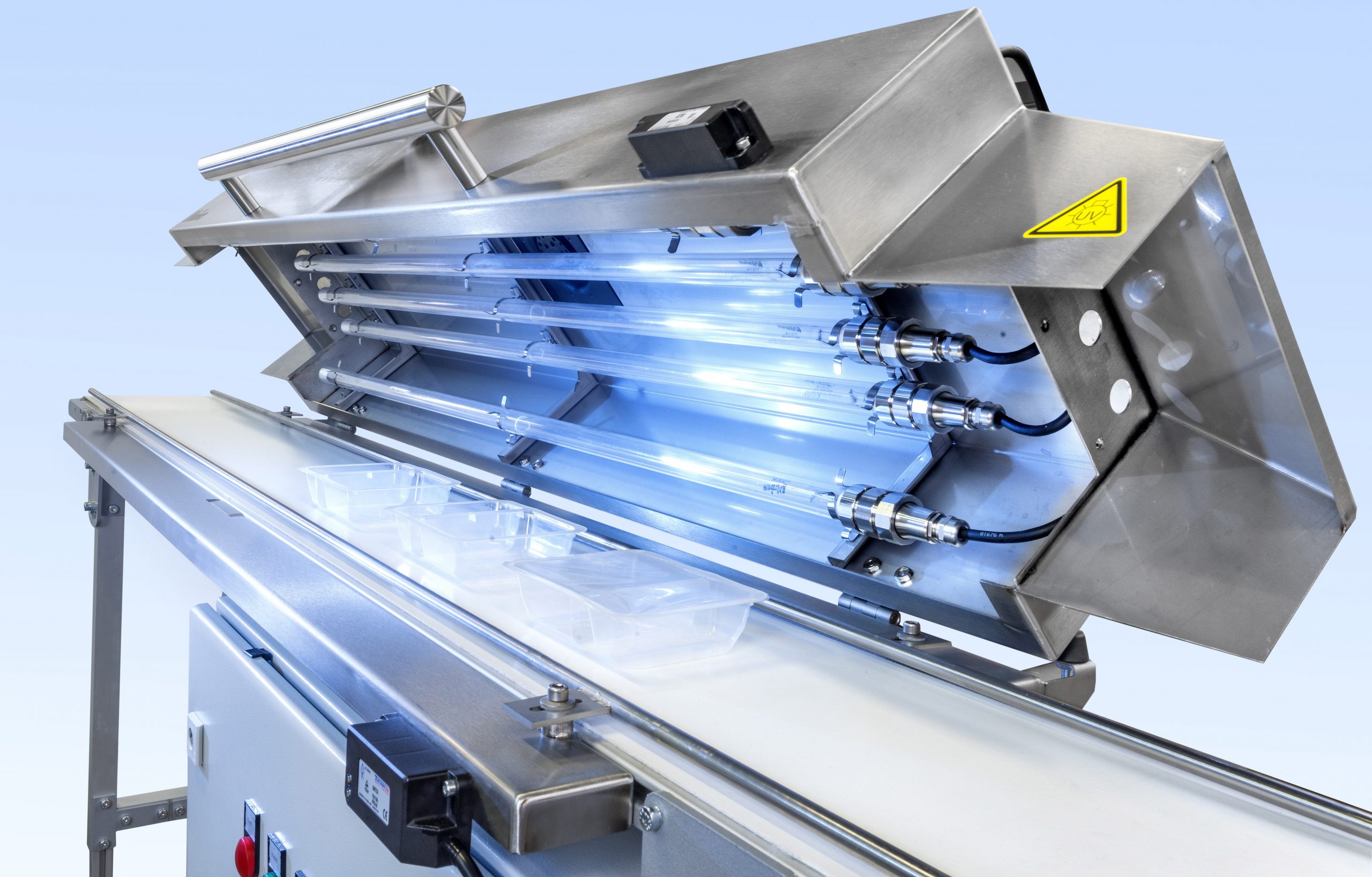

Why This UV Ballast Excels in UV Tunnel Furnaces

Rapid Curing Speed: High-voltage output (up to 2200V) activates photoinitiators instantly, slashing curing time for high-throughput production. This UV lamp controller ensures maximum efficiency.

Uniform Curing Quality: Stable frequency and ripple-free power from this UV driver eliminate hotspots, ensuring consistent results for automotive coatings, flooring, or 3D-printed parts.

Adaptability to Harsh Conditions: Operates in -10°C to +45°C environments. Withstands dust and humidity (≤90% non-condensing), ideal for industrial settings.

Easy Integration: 3x DI/DO, 0-10V Analog I/O: Sync with conveyor belts, temperature sensors, and safety systems. Relay Outputs: Trigger alarms or shutdowns during faults.

Applications in UV Tunnel Furnaces

Automotive: Curing clear coats, primers, and adhesives on car bodies.

Packaging: Instant hardening of UV inks on labels, bottles, and flexible packaging.

Aerospace: Composite material curing for lightweight components.

Electronics: Encapsulation and coating of circuit boards.

Installation & Maintenance

Space Requirements: A≥20mm (side clearance), B≥200mm (top/bottom airflow) for 12KW models.

Cooling: Horizontal mounting recommended; vertical installations require metal heat-dissipation plates.

Warranty: Designed for 24/7 operation with<1% failure rate.

Upgrade Your UV Curing Process Today! Contact FIVER Electronics for Custom Solutions