Medium pressure ultraviolet (UV) has a wide range of applications in wastewater treatment and has many advantages. The following is a detailed introduction for you:

I. Working Principle of Medium Pressure UV System

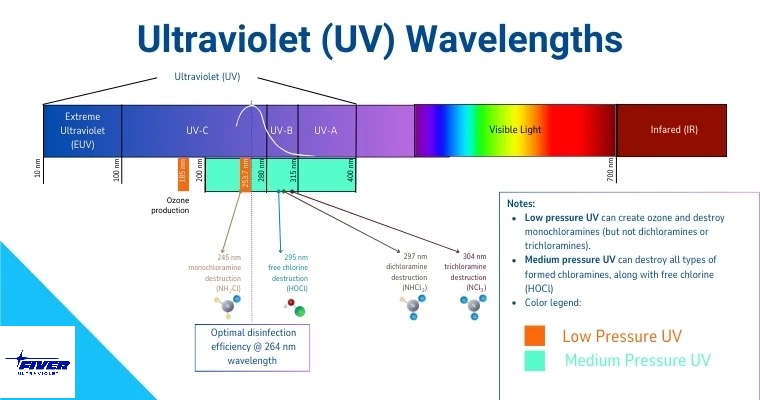

The medium pressure UV disinfection system uses medium pressure UV lamps to emit multi-frequency UV output (the output range is 185 - 400nm). By penetrating the cells of microorganisms and destroying the DNA of microorganisms, microorganisms can no longer reproduce, thus effectively achieving the killing effect. Ultraviolet light with a wavelength between 185 - 400nm (also known as ultraviolet C) has a strong sterilization effect, especially when the wavelength is 265nm, the sterilization effect is better.

II. Application Scenarios of UV Water Disinfection System

1. Municipal Wastewater Treatment: UV System used for disinfect urban sewage after secondary biochemical treatment. It can effectively kill bacteria, viruses and other pathogens in sewage, reduce the risk of disease transmission, and make the treated sewage meet discharge standards or reusable standards. It can be used for urban landscape water, green irrigation, etc.

2. Industrial Wastewater Treatment: Applicable to the industrial wastewater treatment of industries such as pharmaceuticals, chemicals, and printing and dyeing. For example, pharmaceutical wastewater contains a variety of difficult-to-degrade organic pollutants and microorganisms. Medium pressure UV system can assist other treatment processes to deeply disinfect and degrade organic matter in wastewater, reduce the biological toxicity of wastewater, improve biodegradability, and create conditions for subsequent treatment. Chemical wastewater has complex components and high toxicity. Medium pressure UV can effectively inactivate harmful microorganisms in it and reduce environmental pollution. Printing and dyeing wastewater has high chroma and high chemical oxygen demand (COD). Medium pressure UV can reduce COD to a certain extent and kill bacteria and viruses in it, improving wastewater quality.

3. Reclaimed Water Treatment: Disinfect the reclaimed water obtained after advanced treatment of sewage to ensure the hygienic safety of reclaimed water. It can be used in non-potable water links in industrial production such as cooling water and washing water, as well as some domestic miscellaneous water with low water quality requirements, such as flushing toilets and road cleaning, etc., improving the utilization rate of water resources.

4. Special Wastewater Treatment: It can be used to treat hospital sewage and kill pathogens in it to prevent the spread of bacteria. It can also treat landfill leachate to reduce its pollution degree and reduce harm to the environment.

III. Advantageous Characteristics of Medium Pressure UV System for Wastewater Treatment:

Compared with other disinfection technologies, medium pressure uv system has the following advantages in sewage treatment:

I. Broad-spectrum and High-efficiency Sterilization

- In disinfection technologies, medium pressure uv system is outstanding in terms of broad-spectrum sterilization. It can achieve high-efficiency inactivation of almost all bacteria and viruses, including chlorine-resistant microbial tissues such as Legionella pneumophila, Escherichia coli, Pseudomonas, Cryptosporidium, Ameba, and bacteria. In contrast, ozone disinfection may have no effect on certain viruses, and some chemical disinfection methods also have poor killing effects on specific bacteria.

- Medium pressure ultraviolet has high sterilization efficiency and speed. The killing effect on common bacteria and viruses can usually be completed within a few seconds. Compared with some traditional disinfection methods (such as chlorine disinfection), it can achieve disinfection effects more quickly and effectively reduce the number of microorganisms.

II. No Secondary Pollution

- During the disinfection process, uv system does not produce toxic and harmful by-products and does not change the composition and properties of the disinfected water. There is no secondary pollution to the water body and the surrounding environment. For example, chlorination disinfection may produce organic chlorides such as trihalomethanes (THMs) with carcinogenic and teratogenic effects. Ozone disinfection may produce potential carcinogens such as bromate. However, medium pressure uv system does not have such problems.

III. Safe and Reliable Operation

- Compared with some chemical disinfection methods (such as using chlorine gas, etc.) that require safe operation and prevention of dangerous situations such as leakage, the uv water treatment system does not have such safety hazards. It is a disinfection technology that is much safer and more reliable for the surrounding environment and operators.

- Modern medium pressure ultraviolet disinfection technology is usually equipped with an intelligent automatic PLC control system, which can adjust the power of ultraviolet lamps in real time according to flow signals, saving energy and reducing consumption. Moreover, the equipment operates stably and is easy to maintain, which can effectively ensure the safety and stability of the sewage treatment process.

IV. Strong Adaptability

- The generation efficiency of medium pressure ultraviolet lamps is less affected by temperature and can maintain good sterilization effects under different water temperature conditions, suitable for sewage treatment scenarios with various water temperatures. For example, in some industrial wastewater treatment with high water temperature or swimming pool water disinfection, medium pressure ultraviolet has obvious advantages compared with low pressure ultraviolet lamps that are greatly affected by temperature.

- UV water disinfection system is relatively less affected by water quality and has strong adaptability to turbidity and total suspended solids (TSS) of sewage. Within a certain range of turbidity and suspended solid content, it can still maintain good disinfection effects. While some other disinfection methods (such as ultraviolet disinfection) may need to increase pretreatment links to improve disinfection efficiency due to greater influence of turbidity and TSS.

V. Simple and Flexible Operation

- The medium pressure uv disinfection system is modular in design, easy to install, suitable for any installation site conditions, and does not damage the equipment, pipelines and building structures on site. It can be flexibly laid out and installed according to the actual sewage treatment needs.

- Compared with some complex chemical disinfection equipment, the medium pressure ultraviolet disinfection equipment is simple to operate and easy to realize automatic control. There is no need for complex operation processes and professional personnel on duty, which can reduce labor costs.

VI. Continuous Disinfection of Large Water Volume

- At present, medium pressure ultraviolet disinfection technology can already achieve a huge treatment capacity. for example Fiver's FR-UV-MP3KW has a capcacity up to 150T/H, and the FR-UV-MP18KW have the handling capacity up to 800T/H, This is difficult for some other disinfection methods (such as chlorine addition and dechlorination and ozone disinfection methods). It is especially suitable for large-scale sewage treatment projects.

VII. Reducing Combined Chlorine and Improving Water Quality

- Medium pressure ultraviolet has the ability to degrade combined chlorine and can effectively prevent the generation of carcinogenic trihalomethanes. While reducing the pungent smell in the swimming pool, it effectively improves the leisure and sports environment of swimmers and greatly improves the working environment of swimming pool practitioners. Moreover, medium pressure ultraviolet can increase the water penetration rate from 75% to at least 97% or more, effectively improving water quality.

VIII. Small Equipment Footprint and Low Cost

- The medium pressure uv system has a small footprint and can save space, especially suitable for some sewage treatment places with limited space.

- The operation and maintenance cost is relatively low, and it can reach 4 cents or even less per ton of water at the level of thousands of tons of treatment capacity. Although the initial investment in equipment may be high, from a long-term operation perspective, it has good economic efficiency.

IV. Application Cases of Medium Pressure UV System:

1. Lhasa Sewage Treatment Project: In the sewage treatment project in Lhasa, a large medium pressure UV reactor with a single set of treatment water volume of more than 100,000 tons and a maximum power of 192 kilowatts is adopted. The equipment is equipped with ultraviolet intensity probes for monitoring and online temperature monitoring probes to ensure operational safety and stability. Moreover, the power can be adjusted from 50% to 100% according to the incoming water flow signal and the actual UVT signal to achieve energy saving and consumption reduction while ensuring stable sterilization effect. At present, Lhasa has a project performance of 480,000 tons and is equipped with six sets of such medium pressure UV reactors.

2. Other Projects: In many urban sewage treatment plants and industrial wastewater treatment facilities, uv water purification system has been widely used, effectively improving the effect and water quality of sewage treatment and making contributions to environmental protection and the sustainable use of water resources. For example, in some wastewater treatment projects in chemical industrial parks, through the combination of medium pressure UV and other processes, the standard discharge of wastewater has been successfully achieved. In urban reclaimed water utilization projects, medium pressure UV disinfection ensures the hygienic safety of reclaimed water and enables it to be widely used in non-potable water fields in cities.

UV disinfection has gained widespread adoption in WWTPs (Waste Water Treatment Plants) due to its effectiveness and efficiency. However, successful implementation requires careful consideration of factors such as hydraulic properties, UV radiation intensity, and wastewater characteristics.

Factors That Affecting UV Disinfection Effect:

The disinfection effect of ultraviolet disinfection technology is affected by the following factors:

I. Water Quality Factors

1. Turbidity: Suspended particles in water will scatter and absorb ultraviolet rays, weakening the intensity of ultraviolet rays and thus reducing the disinfection effect. Water with high turbidity needs pretreatment to reduce turbidity and improve the penetration ability of ultraviolet rays. so uv system are alway work as secondary or tertiary treatment for wastewater.

2. Chroma: Colored substances will absorb ultraviolet rays and reduce the effective dose of ultraviolet rays. For example, chromatic substances such as dyes in printing and dyeing wastewater will have an adverse effect on the ultraviolet disinfection effect.

3. Soluble organic matter: Some soluble organic matters may compete with microorganisms for the energy of ultraviolet rays or produce a light shielding effect under ultraviolet irradiation, thus reducing the disinfection efficiency.

4. Hardness: Calcium, magnesium and other ions in water may form scale on the surface of ultraviolet lamp tubes, affecting the emission and penetration of ultraviolet rays.

II. Ultraviolet Equipment Factors

1. Ultraviolet intensity: The output intensity of ultraviolet lamp tubes directly affects the disinfection effect. Aging, damage or insufficient power of lamp tubes will lead to a reduction in ultraviolet intensity and thus affect the disinfection efficiency. Our Fiver MP UV systems adopts high quality medium pressure uv lamps, to assure the uv intensity and lifespan, the MP UV system, has integrated uv sensor, what's more the PLC system can continuously monitor key parameters such as uv density, flow rate, pressure and lamp temperature. it can also precisely regulate the UV dose delivered to the water, ensuring consistent disinfection efficiency.

2. Irradiation time: The longer the microorganisms are exposed to ultraviolet irradiation, the greater the possibility of being inactivated. The irradiation time depends on factors such as water flow rate, number of lamp tubes and layout.

3. Lamp tube type: Different types of ultraviolet lamp tubes (such as low-pressure mercury lamps, medium-pressure mercury lamps, etc.) have different spectral characteristics and output intensities, which will also affect the disinfection effect.

4. Equipment maintenance: Regular maintenance and cleaning of ultraviolet equipment to ensure that the lamp tube surface is clean and free of dirt and the normal operation of the equipment are crucial for ensuring the disinfection effect. Fiver's Medium Pressure UV System, has automatic quartz tube wiper, controlled by timer, it can automaticlly clean the quartz sleeves to ensure the uv light transmission and uv disinfection effect.

III. Microbial Characteristics Factors

1. Microbial species: Different types of microorganisms have different sensitivities to ultraviolet rays. Generally speaking, bacteria are more easily inactivated by ultraviolet rays than viruses, but some viruses and bacterial spores may have strong resistance to ultraviolet rays.

2. Microbial quantity: The greater the number of microorganisms in water, the greater the ultraviolet dose required. When the number of microorganisms is too high, it may exceed the processing capacity of ultraviolet disinfection equipment, resulting in poor disinfection effect.

3. Microbial morphology: The morphology of microorganisms will also affect the disinfection effect. For example, larger microorganisms may block smaller microorganisms, reducing the ultraviolet dose they receive and thus reducing the disinfection effect.

IV. Environmental Factors

1. Temperature: Temperature has a relatively small impact on the ultraviolet disinfection effect, but under some extreme temperature conditions, it may affect the performance and life of ultraviolet lamp tubes. Fiver's Medium Pressure UV System have equiped temperature sensor, it can monitor the real-time temperature and turn off the equipment once over-temperature occurs.

2. Humidity: A high humidity environment may cause condensation on the surface of ultraviolet lamp tubes, affecting the emission and penetration of ultraviolet rays.

3. Water flow state: The speed and turbulence degree of water flow will affect the contact time and uniformity of microorganisms and ultraviolet rays, thus affecting the disinfection effect. Steady water flow is conducive to improving the disinfection efficiency.

Post time:2024-09-29