Ultraviolet curing (also known as uv curing) is a technology that uses ultraviolet irradiation to trigger a chemical reaction in a printing, coating or adhesive. This reaction causes the material to solidify or cure almost instantly, providing a durable, high-quality finish.

In this article we will talk about following topics:

1> The Working Principle of UV Curing

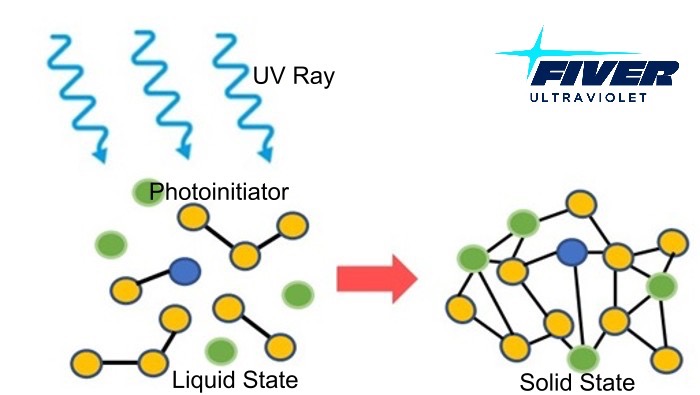

The working principle of uv curing is mainly to use the energy of ultraviolet rays to trigger chemical reactions and thus achieve curing.

Inside the uv curing lamp tube, ultraviolet rays are generated through a special gas discharge process. These ultraviolet rays have specific wavelengths, usually between 200 and 400 nanometers.When ultraviolet rays irradiate the liquid material that needs to be cured, the photoinitiator in the material will absorb the energy of these ultraviolet rays and thus be activated. The activated photoinitiator will trigger the molecules in the material to undergo cross-linking reactions, so that the liquid material quickly changes from liquid to solid and completes the curing process.This process is very rapid and can complete curing in a few seconds or even shorter time, greatly improving production efficiency.

2> Major Components of a UV Curing System:

UV curing machine usually consists of the following components:

- Light source system: The light source system include UV Curing Lamps and UV Lamp Power Supply, which provides ultraviolet irradiation to make the photoinitiator decompose to generate free radicals or cations, and trigger the monomer and oligomer to undergo polymerization and cross-linking curing. According to different light sources, it can be divided into high-pressure mercury lamp, metal halide lamp and UVLED light source, etc.

- Ventilation system: Composed of fan, air outlet pipe and air collecting hood, it is used to remove the heat and exhaust gas generated during the curing process and maintain the temperature and air quality inside the equipment.

- Control system: Used to control the operation of the entire equipment, including the switch of the light source, power adjustment, temperature control, conveying speed control, etc.

- Conveyor system: Composed of a speed-regulating motor (or frequency conversion speed regulation), a transmission mesh belt and a chain (or transmission roller), it is used to transport the cured material so that it can be evenly irradiated under the light source.

- Box body: Used to accommodate and protect other components of the equipment, and at the same time provide a safe working environment.

In addition, according to different application requirements, ultraviolet curing equipment may also be equipped with other auxiliary components such as a reflector, a shading cover, a cooling system, etc.

3> The Applications of Ultraviolet Curing

Ultraviolet curing has the advantages of high efficiency, environmental protection, and energy saving, and is widely used in multiple fields. The following are some common application scenarios:

1. Printing industry

- Offset printing: In offset printing, ultraviolet curing technology can be used for surface glazing of printed matter, such as book covers, picture albums, packaging boxes, etc. It can make the surface of printed matter dry quickly and has high gloss, wear resistance, and chemical resistance.

- Silk screen printing: Applicable to silk screen printing on various materials such as plastic, metal, glass, and ceramics. Ultraviolet curing ink can cure quickly in silk screen printing, realizing fine pattern printing and having good adhesion and weather resistance.

- Flexographic printing: Ultraviolet curing flexographic printing is often used for printing labels, packaging paper, plastic films, etc. Its curing speed is fast, which can improve printing efficiency and at the same time meet the printing needs of various substrates.

2. Electronic industry

- Circuit board manufacturing: In the production process of circuit boards, ultraviolet curing is used for the curing of anti-corrosion agents and solder resists, as well as the character printing of circuit boards. It can achieve high-precision pattern curing and ensure the quality and performance of circuit boards.

- Electronic component packaging: For the packaging of electronic components such as diodes, transistors, and integrated circuits, ultraviolet curing adhesives can cure quickly, providing good sealing and protection effects. At the same time, it has a low shrinkage rate and reduces the stress on components.

- Touch screen manufacturing: Ultraviolet curing technology is used for the curing of the optical transparent adhesive (LOCA) of touch screens. It can provide strong adhesion, isolate moisture infiltration, and have excellent optical properties such as light transmittance and reduced reflection without causing image distortion.

3. Home decoration

- Furniture surface coating: It can be applied to the curing of coatings on the surfaces of wooden furniture, metal furniture, etc., making the furniture surface have good wear resistance, scratch resistance, and aesthetics.

- Floor coating: Ultraviolet curing floor paint can cure quickly to form a hard and wear-resistant coating, improving the service life and decorative effect of the floor.

- Wallpaper production: Used for the printing and coating curing of wallpapers, making the wallpaper patterns more vivid and lasting, and the production process is more environmentally friendly and efficient.

4. Automotive industry

- Automotive parts coating: For the surface coating of automotive parts such as bumpers, rearview mirrors, and wheels, ultraviolet curing coatings can dry quickly, improve production efficiency, and have good weather resistance and corrosion resistance.

- Automotive interior parts manufacturing: Used in printing and bonding processes of automotive interior parts, such as surface decoration of parts such as instrument panels, door panels, and seats and bonding and fixing of functional parts.

5. Medical industry

- Medical device manufacturing: Ultraviolet curing adhesives can be used for the assembly and packaging of medical devices such as disposable syringes, catheters, and surgical instruments to ensure the sterility and reliability of products.

- Dental field: Used for the curing of dental materials such as filling materials and adhesives for dental braces. It can cure quickly, facilitating doctor's operations and reducing patient waiting time.

6. 3D printing

In some 3D printing technologies such as stereolithography (SLA) and digital light processing (DLP), ultraviolet curing is used to quickly cure liquid photosensitive resins into solid three-dimensional objects, realizing the production of high-precision and complex-structured models.

7. Optical field

-Optical lens coating: Used for the curing of anti-reflective coatings, anti-reflective coatings, etc. on optical lenses to improve the optical performance of the lenses.

-Optical fiber manufacturing: In the production process of optical fibers, ultraviolet curing is used for the curing of optical fiber coatings to protect the surface of optical fibers and improve the strength and durability of optical fibers.

8. Other fields

-Building materials industry: Such as the curing of sealants for glass curtain walls and the curing of ceramic tile beauty sealants. Ultraviolet curing technology can provide a fast and firm bonding effect.

-Plastic processing: Used for printing and coating curing of plastic products such as plastic films, pipes, and plates to increase the added value and functionality of plastic products.

4> The Advantages of UV Curing Technology:

UV curing has the following advantages or characteristics:

1. Fast curing speed: Ultraviolet curing technology can rapidly cure materials in a few seconds or even milliseconds, greatly improving production efficiency and meeting the needs of large-scale and high-efficiency industrial production. For example, in the printing industry, it can quickly dry ink and achieve high-speed printing.

2. Good curing effect: The cured material has good physical and chemical properties, such as high hardness, strong wear resistance, and good corrosion resistance, which can improve product quality and service life. For example, in electronic component packaging, it can provide reliable protection and stable performance for electronic components.

3. Environmental protection and energy saving: The uv curing technology basically has no solvent evaporation during the curing process, reducing environmental pollution, and has relatively low energy consumption. It meets the requirements of environmental protection and sustainable development and conforms to the current trend of green production.

4. Strong applicability: It can be applied to a variety of materials, including coatings, inks, adhesives, plastics, wood, etc., and can meet the diverse needs of different industries. For example, in the furniture industry, it can be used for the curing of coatings on wood surfaces; in the automotive industry, it can be used for the curing of car paint and glue.

5. High space utilization rate: Ultraviolet curing equipment is usually compact and small, occupying not too much space. It is particularly applicable to production sites with limited space and can effectively improve space utilization.

6. Advantages of trenchless repair: In fields such as pipeline repair, ultraviolet curing trenchless technology has unique advantages. It can repair without destroying pavements or buildings, reducing the impact on the surrounding environment and traffic and lowering repair costs and social costs. It has broad market application space, such as the repair of urban underground pipelines.

5>The Market Prospect of Ultraviolet Curing Industry

1. Continuous technological progress: Increasing research and development investment has promoted the continuous improvement of ultraviolet curing technology in aspects such as light source efficiency, curing speed, and material performance. While reducing costs, it further improves the competitiveness of the technology and broadens the application range. For example, the research and development of new photoinitiators and the development of more efficient ultraviolet light sources will all promote the development of ultraviolet curing technology.

2. Industrial collaborative development: The development of ultraviolet curing technology and related industries such as raw material supply, equipment manufacturing, and downstream application industries promote each other and develop collaboratively. Raw material suppliers continuously launch ultraviolet curing materials with better performance and lower cost. Equipment manufacturers continuously improve the stability and intelligence level of equipment. The growth in demand for ultraviolet curing technology in downstream application industries, in turn, promotes technological and industrial progress, forming a virtuous circle and jointly promoting market prosperity.

3.Good growth trend in the global market: Globally, the ultraviolet curing technology market shows a growth trend in all regions. In the Asia-Pacific region, due to the rapid development of manufacturing and the improvement of environmental protection requirements, the demand for ultraviolet curing technology is growing rapidly. In Europe and America, the continuous deepening of applications in high-end manufacturing, electronics, healthcare and other fields also promotes market development. According to relevant market research reports, it is expected that the global ultraviolet curing market size will continue to maintain a high growth rate in the next few years.

However, the market prospect of uv curing technology also faces some challenges, such as the high cost of some raw materials and the shortage of technical talents. But in general, its advantages and positive factors such as market demand are obvious, and the market prospect is relatively optimistic. In the future, it is expected to continue to maintain a rapid development trend and be widely used in more fields.

Post time:2024-10-06