Ultraviolet (UV) light, an invisible part of the electromagnetic spectrum, has a wide range of applications that impact our daily lives in ways we often don't realize. From sterilizing surfaces to curing industrial coatings, UV lamps play a crucial role in various sectors. As a leading manufacturer of UV lamps, FIver Electronic Technology Co.,ltd is dedicated to providing high-quality, reliable solutions for diverse needs. This article explores the fascinating world of UV light and the versatile applications of UV lamps

What is UV Light?

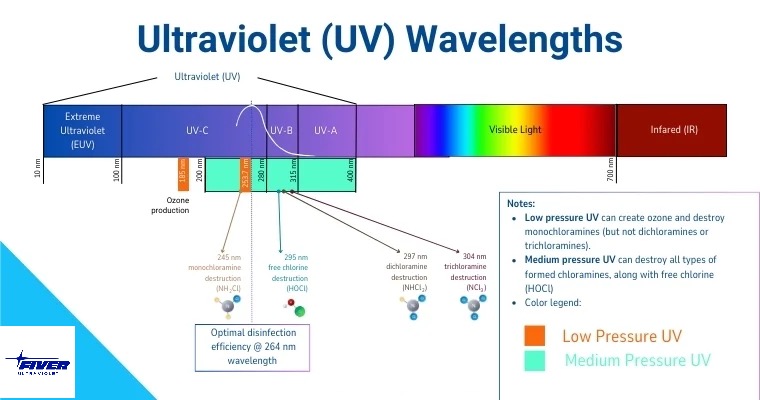

UV light occupies a specific range on the electromagnetic spectrum, lying between visible light and X-rays. It's further categorized into three primary bands,known as UV-A, UV-B and UV-C each with distinct properties and applications:

UV-A (315-400 nm): Also known as "black light," UV-A is the least energetic form of UV radiation and is used in tanning beds, counterfeit detection, and insect traps.

UV-B (280-315 nm): UV-B has higher energy than UV-A and is responsible for sunburn. It is also used in phototherapy for certain skin conditions.

UV-C (100-280 nm): UV-C is the most energetic form of UV radiation and is highly effective at killing bacteria, viruses, and other microorganisms. It is primarily used for disinfection and sterilization

What is A UV Lamp and How Does It Works?

A UV lamp, also known as an ultraviolet lamp, is a type of light source that emits ultraviolet radiation. Ultraviolet radiation is a form of electromagnetic radiation with wavelengths shorter than those of visible light but longer than X-rays

How UV Lamps Work?

Most UV lamps work on the principle of passing an electric current through a gas, typically mercury vapor. This excites the mercury atoms, causing them to emit UV radiation. The specific wavelengths emitted depend on the gas used and the lamp's design

Types of UV Lamps/UV Light Bulbs

There are several types of UV lamps, each with its own characteristics and working mechanisms

Low-pressure Mercury Vapor Lamps: These are commonly used for germicidal applications. They work by passing an electric current through a small amount of mercury vapor at low pressure. The mercury atoms are excited and emit UV light mainly at 253.7 nm wavelength, which is highly effective for killing bacteria, viruses, and other microorganisms by disrupting their DNA and RNA.

Medium-pressure Mercury Vapor Lamps: They operate at higher pressures and temperatures compared to low-pressure lamps. They emit a broader spectrum of UV light, including wavelengths in the UV - A, UV - B, and UV - C ranges. These lamps are often used in industrial applications such as UV curing of inks and coatings. The higher power and broader spectrum allow for faster curing processes as the UV light causes chemical reactions in the materials being cured, leading to polymerization and hardening.

UV - LED lamps: UV - LED lamps use light-emitting diodes to emit ultraviolet light. They are becoming increasingly popular due to their energy efficiency, longer lifespan, and smaller size compared to traditional mercury vapor lamps. The working of UV - LED lamps is based on the semiconductor properties of the materials used. When an electric current is applied to the semiconductor material, electrons recombine with holes, and energy is released in the form of UV photons. Different semiconductor materials can be used to produce UV light at different wavelengths, making UV - LED lamps suitable for a wide range of applications from medical to industrial.

In this article we are mainly focus on low-pressure mecury lamps & Medium-pressure mercury lamps.

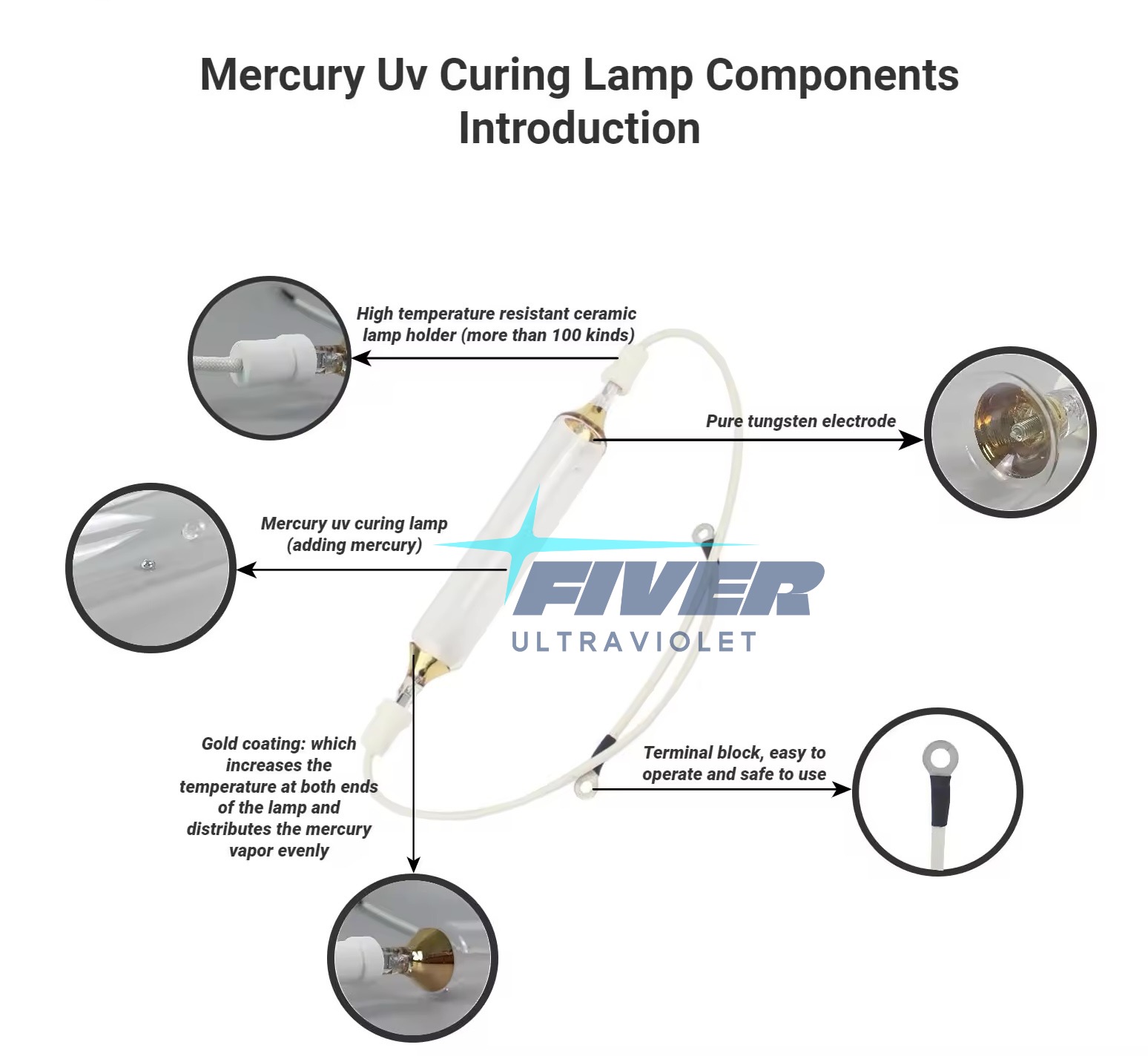

The Construction Components of a Mecury UV lamp

1. Lamp Tube

The lamp tube is the main body that houses the other components and provides a sealed environment for the internal processes. It is usually made of quartz glass in the case of most UV lamps, especially those emitting shorter wavelengths (such as UVC lamps). Quartz is chosen because it has excellent transparency to ultraviolet light and can withstand the high temperatures and chemical conditions that occur during lamp operation. For some UV - A or UV - B lamps, borosilicate glass may also be used, which is more cost-effective and suitable for applications where the UV wavelengths are less critical and the operating conditions are less harsh.

2. Electrodes

Electrodes are essential for initiating and maintaining the electrical discharge within the lamp. In a traditional mercury vapor UV lamp, for example, there are usually two electrodes, one at each end of the lamp tube. These electrodes are made of a conductive material, often tungsten or a tungsten alloy. When an electrical voltage is applied across the electrodes, it ionizes the gas (such as mercury vapor) inside the lamp tube, creating a plasma. The plasma is a conductive medium that allows the flow of electric current, which in turn excites the atoms or molecules in the gas, leading to the emission of ultraviolet light. In some modern UV - LED lamps, the electrodes are replaced with semiconductor structures that facilitate the movement of electrons to produce UV light through a different mechanism.

3. Filling Gas

The filling gas inside the lamp tube plays a crucial role in the emission of UV light. In mercury vapor lamps, mercury is the primary filling gas. When the lamp is energized, the mercury atoms are excited and emit ultraviolet radiation at specific wavelengths, with the most prominent emission at 253.7 nm for germicidal applications. In addition to mercury, other gases may also be present in small amounts. For example, argon is often added to help start the discharge process more easily. In some UV lamps, other noble gases or gas mixtures may be used to modify the spectral output or improve the lamp's performance characteristics. In UV - LED lamps, the semiconductor material itself determines the wavelength of the emitted UV light, and there is no traditional "filling gas" in the same sense as in mercury vapor lamps.

4. Phosphor Coating (Optional)

In some UV lamps, a phosphor coating is applied to the inner surface of the lamp tube. This is more common in lamps used for applications such as UV curing or where a specific spectral output is desired. The phosphor coating absorbs the UV light emitted by the excited atoms or molecules (such as from mercury vapor) and then re-emits light at a different, usually longer, wavelength. This process can be used to convert the UV light into a more suitable wavelength range for a particular application. For example, in a UV curing lamp, the phosphor coating may be used to convert the initial UV emission to a wavelength that is more efficiently absorbed by the photosensitive materials being cured, enhancing the curing process.

5. Base or Socket

The base or socket is the part of the UV lamp that connects it to the power supply and the ballast or driver. It provides a mechanical and electrical connection, ensuring a secure fit and proper electrical contact. Different types of UV lamps may have different base designs, such as a bi-pin base, a mogul base, or a specialized LED module connector. The base must be compatible with the corresponding socket in the lamp fixture to ensure proper installation and operation. It also needs to be designed to handle the electrical currents and voltages associated with the UV lamp and provide a reliable connection over the lamp's lifespan.

The Applications of UV Lamps/Ultraviolet Light Bulbs

Sterilization Applications

UVC ultraviolet lamps are widely used for sterilization and can effectively eliminate harmful pathogens and microorganisms in the air, water, and on surfaces, playing an important role in hospitals, laboratories, restaurants, food processing, and various air and water purification systems.

Tanning Purposes

UVA lamps are the main lamps used in tanning beds and can tan human skin, but excessive use can lead to skin aging and other problems.

UV Curing

In some industrial production processes, UV curing lamps can be used to cure materials. For example, in the fields of printing and coating curing, materials can be quickly cured by UV irradiation, improving production efficiency and product quality. know more about the Applications and Advantages of UV Curing

Lighting and Signage

In some special scenarios, UV lamps can be used for lighting and making signs. For example, in museums, exhibition halls, and other places, they are used to highlight exhibits or display special marks, and they are also used in some entertainment venues to create a special atmosphere.

Backlight Applications

For example, it is used for backlight illumination in the aviation field to provide special lighting effects for instrument panels and improve visibility and safety.

Medical Phototherapy

UVB and UVA lamps can be used to treat a variety of skin diseases, mood disorders, and other health problems, such as treating skin diseases like psoriasis and vitiligo, and mood disorders like seasonal affective disorder.

UV Lamp Products of Fiver Electronic Technology

Fiver Electronic Technology, as a manufacturer of various types of UV lamps, offers a variety of high-quality UV lamp products. Our products cover UVC sterilization lamps, UV lamps used in tanning beds, far UVC lamps, and UV phototherapy lamps, UV curing lamps which can meet the needs of different industries and application scenarios. Whether it is sterilization and disinfection, industrial production, medical care, or other special uses, we can provide customers with suitable UV lamp solutions. At the same time, we also provide custom design and engineering services to meet the specific UV lamp requirements of customers and follow strict quality policies to ensure excellent product quality. If you have a demand for UV lamps, please feel free to contact us. Our engineers will provide you with professional consultation and services to help you obtain high-quality UV lamps that are most suitable for your application.

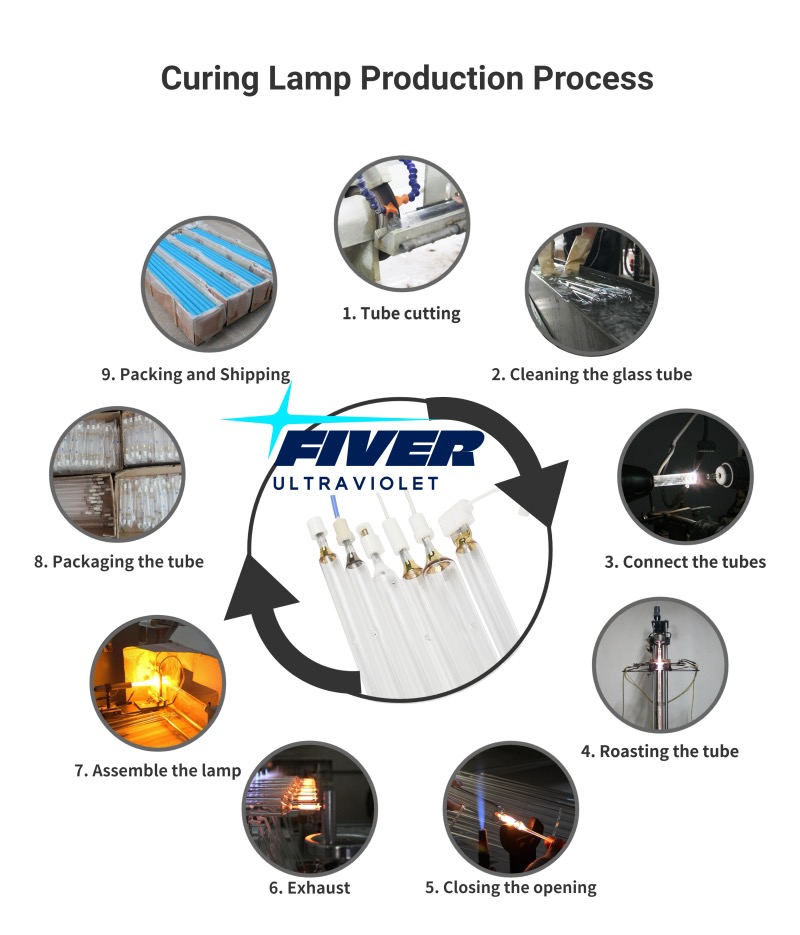

How UV Lamps are Made?

Post time:2024-12-23