In today's fast-paced electronics industry, the demand for smaller, more complex Printed Circuit Boards (PCBs) is constantly increasing. This puts immense pressure on manufacturers to optimize every stage of production, with PCB exposure being a critical bottleneck. Achieving precise pattern transfer and maximizing throughput is essential for staying competitive. That's where Iodine Gallium UV exposure lamps—a vital component of PCB manufacturing supplies—come into play, offering a powerful and proven solution for PCB UV exposure.

Why PCB Exposure Matters (and Why It Needs to Be Perfect)

Think of PCB exposure as the photographic process of creating your circuit board. A photosensitive material, often called photoresist PCB or photosensitive paint, is applied to a copper-clad board. Then, UV light pcb, passing through a photomask (like a stencil), hardens the areas that will become the conductive pathways. This hardened resist protects the copper during the etching process, leaving behind the intricate circuit pattern. Any inaccuracies during exposure, using the wrong uv lamp for pcb exposure, can lead to flawed circuits, costly rework, and production delays. This is why choosing the right pcb uv light is essential.

Iodine Gallium Lamps: The UV Workhorses of PCB Manufacturing

Several UV light sources exist, but Iodine Gallium lamps have earned their place in PCB manufacturing for some key reasons:

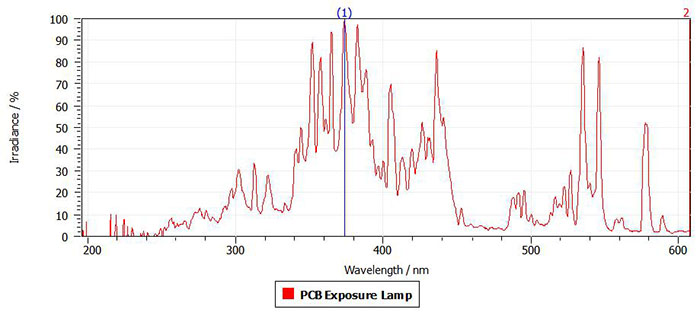

The Right Light for the Job (Spectral Matching): Photoresist pcb materials are designed to react most efficiently to specific wavelengths of UV light. Iodine Gallium lamps shine in the UVA range, with a crucial peak at 417nm. This wavelength is a sweet spot for many commonly used photoresists, maximizing energy absorption and ensuring a clean, precise exposure. It's like using the right key for the right lock – it just works better. This makes them an ideal uv lamp for pcb exposure.

Speed and Efficiency (High Intensity): In high-volume PCB production, time is money. Iodine Gallium lamps deliver high-intensity UV light, drastically reducing exposure times. This faster processing translates directly to increased throughput, allowing you to produce more boards in less time. This is a significant advantage when considering pcb uv exposure.

Even Light Distribution (Uniform Illumination): Imagine trying to take a photograph with a flashlight that has a patchy beam. You'd get uneven exposure and a blurry image. The same applies to PCB exposure. Iodine Gallium lamp systems are designed with reflectors and optics to provide uniform illumination across the entire PCB surface, ensuring consistent pattern transfer and preventing costly defects. This even distribution is crucial for effective pcb uv light applications.

What Makes Iodine Gallium Lamps a Smart Choice for PCB Production?

Razor-Sharp Circuitry: The precise pattern transfer facilitated by the 417nm peak ensures the creation of fine lines and intricate circuit designs, meeting the demands of high-density interconnect (HDI) PCBs.

Faster Turnaround Times: Shorter exposure times mean faster production cycles, allowing you to meet tight deadlines and deliver products to market quicker.

A Proven and Reliable Technology: Iodine Gallium lamps have a long track record in PCB manufacturing, providing a reliable and cost-effective solution for many years. They are a staple in pcb manufacturing supplies.

Important Considerations for Optimal Performance of UV Lamp for PCB Exposure:

Regular Lamp Maintenance: Like any uv lamp for pcb exposure, Iodine Gallium lamps experience a gradual decrease in output over time. Regular monitoring and timely replacement are crucial for maintaining consistent exposure results for pcb uv exposure.

Safety First: UV radiation can be harmful. Always use proper eye and skin protection when working with pcb uv light and other UV exposure lamps. Ensure adequate ventilation to manage any ozone generated by the lamps, this is important safety information for users of pcb manufacturing supplies.

Proper Cooling is Essential: These lamps generate heat and require effective cooling systems to prevent overheating and ensure optimal performance and lifespan.

The Bottom Line: Iodine Gallium Lamps Deliver for PCB Manufacturers

While UV LED technology is rapidly advancing, Iodine Gallium lamps remain a strong contender in the PCB manufacturing landscape, especially when considering cost-effectiveness and high-volume production. Their unique spectral output, high intensity, and proven reliability make them a valuable tool for achieving precise pattern transfer and maximizing production efficiency for pcb uv exposure.

Post time:2025-01-16