In the world of hardwood flooring, achieving a perfect finish is both an art and a science. UV curing lamps have emerged as a game-changing technology that is transforming the way hardwood floors are finished. This article delves into the various aspects of UV curing lamps in hardwood floors, exploring their functionality, benefits, and the impact they have on the flooring industry.

The Science Behind UV Curing Lamps

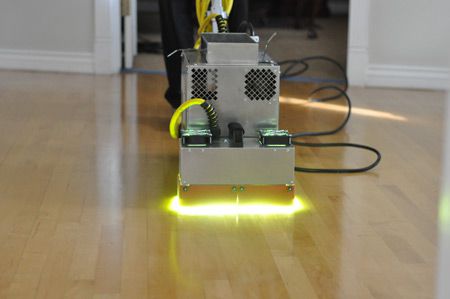

UV curing lamps operate on a fascinating principle. They emit ultraviolet light, which triggers a chemical reaction in specially formulated coatings applied to hardwood floors. These coatings consist of key components such as photoinitiators, oligomers, and monomers. When the UV light hits the coating, the photoinitiators absorb the light energy and produce free radicals. These radicals then initiate a chain reaction, causing the oligomers and monomers to link together and form a solid, durable film. This process occurs almost instantaneously, typically within seconds, as opposed to the days required for traditional finishes to cure.

Advantages of UV Curing Lamps in Hardwood Floors

1. Rapid Curing and Immediate Use

One of the most significant advantages of ultraviolet light lamps is the speed at which they cure the floor finish. In a matter of minutes, the hardwood floor is transformed from a freshly coated surface to a fully cured and hardened one. This means that homeowners and businesses can resume using the space almost immediately. For example, in a busy commercial setting like a hotel lobby or a retail store, renovations can be completed quickly, minimizing downtime and disruption to operations. In a residential context, homeowners can move furniture back into the room and start enjoying their newly finished floors right away.

2. Superior Durability and Resistance

UV cured finishes offer exceptional durability compared to traditional finishes. The hardened layer created by the UV curing process provides excellent resistance to scratches, scuffs, and stains. This is especially crucial in high-traffic areas such as hallways, living rooms, and commercial spaces. The finish remains intact even under heavy use, maintaining the beauty and integrity of the hardwood floor for years to come. It also resists fading from sunlight exposure, ensuring that the color and appearance of the floor stay vibrant over time.

3. Environmental Benefits

Ultraviolet curing lights are an environmentally friendly alternative to traditional curing methods. They significantly reduce volatile organic compound (VOC) emissions, which are harmful chemicals that can have a negative impact on indoor air quality and the environment. Additionally, the curing process consumes less energy compared to heat-curing methods, making it a more energy-efficient option. This not only benefits the environment but also aligns with the growing demand for sustainable building practices.

4. Customizable Finishes

UV curing technology allows for a wide range of customizable finishes. Homeowners and designers can choose from different sheens, including glossy, satin, and matte, to achieve the desired aesthetic. A variety of colors and stains are also available, enabling them to match the flooring with the overall interior design theme. Moreover, unique patterns and designs can be created, adding a personalized touch to each hardwood floor.

The Application Process

1. Preparation and Safety Measures

Before using a UV curing lamp, proper preparation is essential. The area must be cleared of furniture and debris, and the floor should be thoroughly cleaned to remove any dust or particles. Masking off baseboards and walls with tape protects them from the coating. Safety precautions are also crucial. Operators should wear protective gloves and eye protection to shield themselves from the UV light. Adequate ventilation is necessary to prevent the buildup of fumes. Warning signs should be posted to inform others about the ongoing UV curing process.

2. Professional Application Techniques

UV curing lamps are typically used by trained professionals due to the specialized equipment and expertise required. The UV-sensitive coating is evenly applied to the hardwood floor using rollers. Specialized UV lamps, designed specifically for flooring applications, are then used to expose the coating to the ultraviolet light. The intensity and duration of the UV exposure are carefully controlled to ensure proper curing. Once the curing process is complete, the floor is immediately ready for use.

Maintenance and Care for the UV Cured Hardwood Floors

1. Cleaning Protocols

Proper cleaning is essential to maintain the beauty and durability of UV cured hardwood floors. Regular sweeping with a soft-bristle broom or vacuuming with a hardwood floor setting helps remove dirt and dust. Weekly mopping with a microfiber mop is recommended, using cleaners specifically formulated for UV cured wood floors. Harsh chemicals should be avoided as they can damage the UV coating. Spills should be wiped up immediately to prevent staining. For a deeper clean, professional hardwood floor cleaners can be used, ensuring they are compatible with the UV cured finish.

2. Repair and Recoating

In case of minor scratches, repair kits can often be used to buff out the damage. For deeper scratches, the affected area should be cleaned thoroughly, a matching wood filler applied, and once dry, gently sanded. A new coat of UV cured finish can then be applied. Recoating may be necessary over time to maintain the floor's appearance and durability. It is advisable to consult a professional for recoating, as they have the necessary equipment and expertise to ensure a proper and efficient application.

Future Trends and Innovations of the UV Curing Light for Hardwood Floors

The future of UV curing lamps for hardwood floors looks promising, with ongoing research and development focused on enhancing their performance. Innovations on the horizon include self-healing finishes that can automatically repair minor scratches, further improving the durability of the floors. Enhanced scratch resistance is being developed, especially for high-traffic areas, to withstand even more wear and tear. Additionally, customizable gloss levels will offer even more design flexibility, allowing homeowners and designers to create unique and personalized flooring looks. The growing demand for UV cured hardwood floors is driving these advancements, making the technology more accessible and cost-effective for a wider range of applications.

UV curing lamps have truly revolutionized the hardwood floor finishing industry. Their ability to provide rapid curing, superior durability, environmental benefits, and customizable finishes makes them an ideal choice for both residential and commercial applications. As technology continues to evolve, we can expect even more exciting developments in the future, further enhancing the beauty and longevity of hardwood floors.

Post time:2024-12-19