Custom Iodine Gallium UV Lamps for Flexo Printing | Fiver Electronic Technology

High-Performance UV Curing Solutions for Flexo Printing

Custom Iodine Gallium Lamps by Fiver Electronic Technology

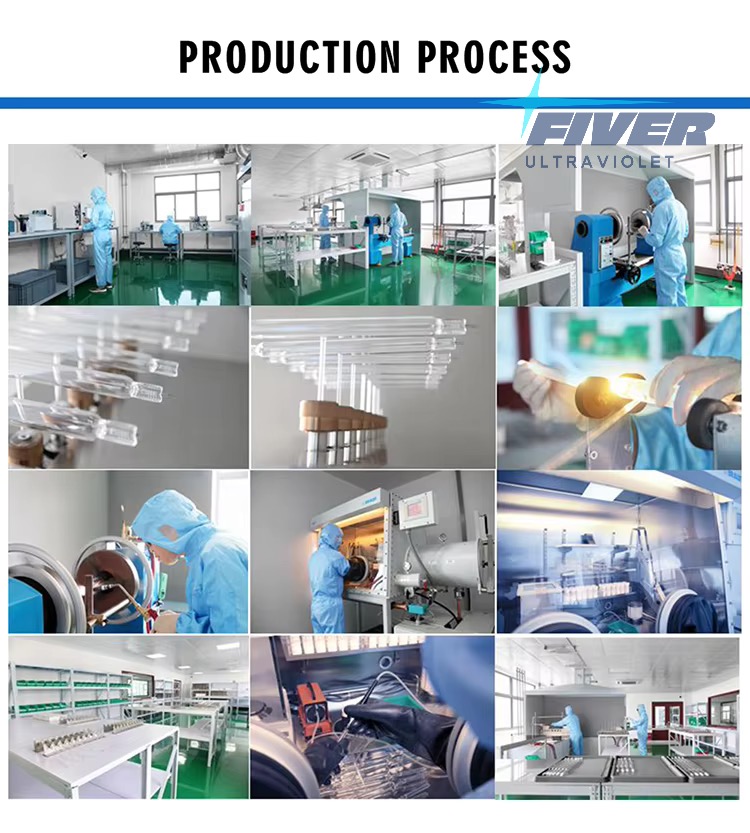

At Fiver Electronic Technology, we specialize in designing advanced UV curing systems that redefine efficiency and quality in flexographic (flexo) printing. As a trusted manufacturer of iodine gallium (Ga-I) UV lamps, we deliver tailored solutions to meet the unique demands of packaging, labels, and industrial film production. Our mercury-free, energy-efficient lamps are engineered to optimize your workflow, reduce costs, and ensure compliance with global sustainability standards.

Why Choose Iodine Gallium Lamps for Flexo Printing?

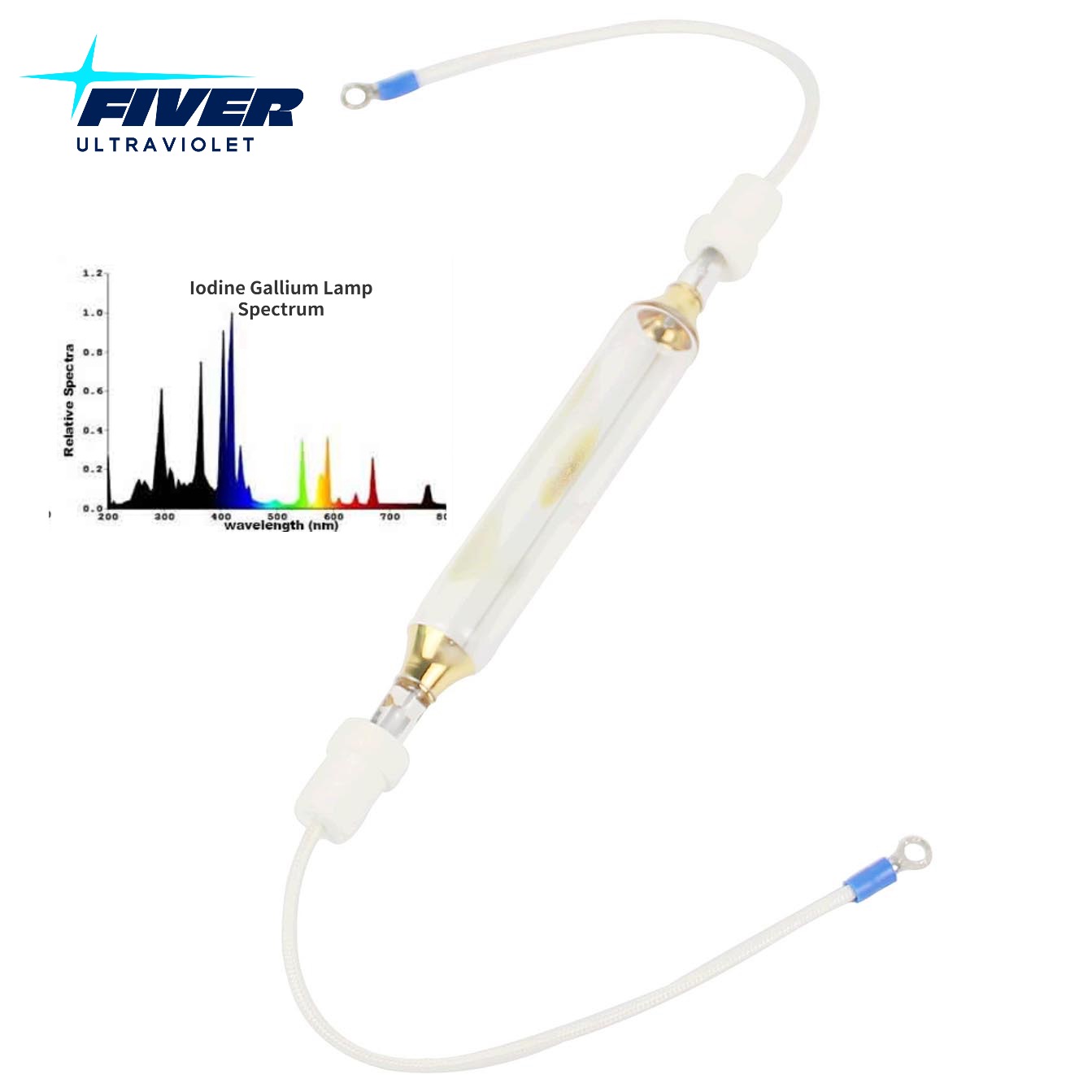

Iodine gallium UV lamps are revolutionizing flexo printing with their superior performance and eco-friendly design. Here’s why they outperform traditional mercury-based systems:

1. Eco-Friendly & Sustainable

Mercury-Free Design: Comply with strict regulations like RoHS and REACH while eliminating hazardous waste disposal.

Low Ozone Emissions: Reduced UVC radiation ensures safer working environments and no ozone generators required.

2. Faster, Consistent Curing

Targeted UVA Spectrum (403–418 nm): Perfectly aligns with modern UV ink photoinitiators for rapid curing of opaque, metallic, or thick ink layers.

Instant On/Off Functionality: Eliminate warm-up delays and reduce downtime in start-stop production cycles.

3. Energy & Cost Efficiency

Lower Heat Output: Protect heat-sensitive substrates like PET films and shrink sleeves from warping.

30% Energy Savings: Advanced electrical-to-UV conversion reduces power consumption compared to mercury lamps.

4. Unmatched Print Quality

Sharper Details: Precise curing minimizes dot gain and enhances edge definition for vibrant colors and crisp graphics.

Durable Finishes: Achieve scratch-resistant, high-gloss coatings ideal for premium packaging and labels.

Tailored Solutions for Your Flexo Printing Needs

At Fiver Electronic Technology, we don’t believe in one-size-fits-all solutions. Our iodine gallium lamps are fully customizable to align with your production requirements:

Customization Options

Spectral Output Tuning: Optimize wavelengths to match your inks, coatings, or adhesives.

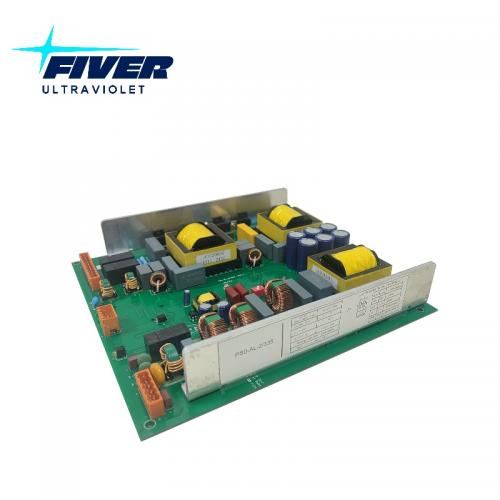

Modular Lamp Designs: Retrofit existing systems or integrate into new presses (narrow web, wide web, or sleeve-based).

Power Density Adjustments: Scale from 120 W/cm² to 240 W/cm² for high-speed curing (200+ meters/minute).

Cooling Systems: Choose air- or water-cooled configurations to manage thermal loads.

Applications We Serve

Food & Pharmaceutical Packaging: Low-migration curing for compliant, odor-free inks.

Pressure-Sensitive Labels & Shrink Sleeves: High-speed curing without compromising adhesion.

Industrial Films: Durable coatings for moisture barriers, anti-scratch layers, and UV protection.

Why Partner with Fiver Electronic Technology?

Expertise You Can Trust

With decades of experience in UV curing technology, we understand the challenges of flexo printing. Our engineers work closely with you to:

Conduct spectral analysis of your inks and substrates.

Optimize lamp configurations for speed, quality, and energy savings.

Provide 24/7 technical support for seamless integration and troubleshooting.

Proven Benefits for Your Business

✅ Extended Lamp Lifespan: 2,000–3,000 hours of reliable operation.

✅ Reduced Maintenance: Fewer replacements and lower downtime.

✅ Future-Proof Compliance: Stay ahead of environmental regulations.

Upgrade to Sustainable UV Curing Today

Ready to enhance your flexo printing process? Fiver Electronic Technology’s iodine gallium lamps deliver:

Faster production speeds

Lower operational costs

Brighter, longer-lasting prints

A smaller environmental footprint

Contact Us for a Custom Quote

Email: Jerry@fiveruvc.com