Customize Iodine Gallium Lamp 400w to 8KW Uv Curing Lamp for printing Industry

Customize Iodine Gallium Lamp 400w to 8KW Uv Curing Lamp for printing Industry

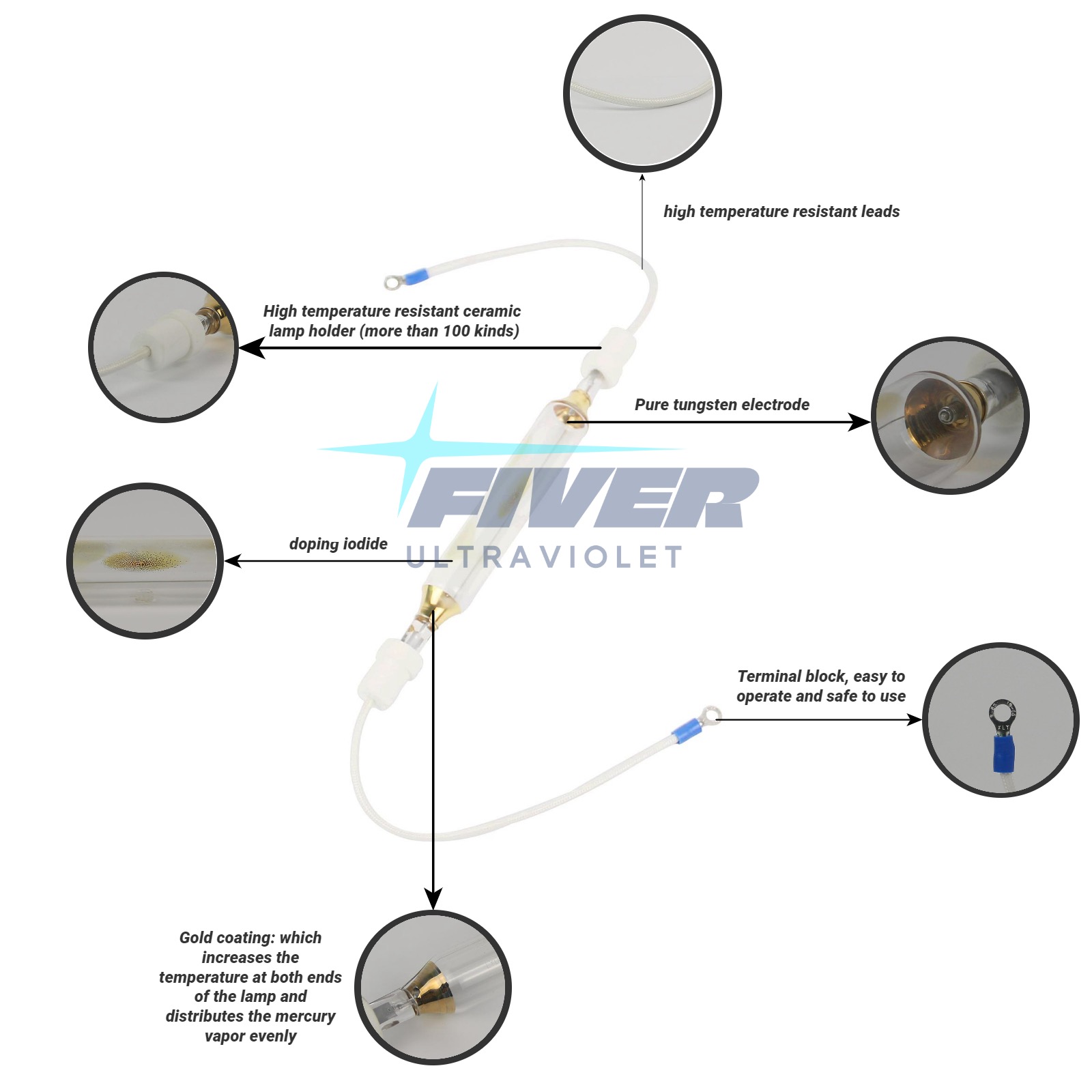

Iodine Gallium lamps are kind of metal halide lamps doped with gallium iodide.

Product Parameters of Iodine Gallium Lamp From Fiver

As a leading manufacturer of UV curing solutions, Fiver Electronic Technology specializes in crafting tailor-made Iodine Gallium lamps to meet the diverse demands of the modern printing industry. We understand that achieving consistent quality and maximizing efficiency requires precision-engineered equipment. From intricate screen printing to high-speed flexographic presses, our customizable Iodine Gallium lamps, ranging from 400W to 40000W, are designed to optimize your specific printing workflow.

| Parameter Range of Iodine Gallium Lamps From Fiver | |

| Power output | 500w to 40kw |

| Wavelength | 320nm to 450nm Peak( 403nm, 417nm) |

| Arc length | 50mm to 2000mm |

| Tube diameter | 18mm to 32mm |

| Power density | 30/60/80/120/160/200 w/cm |

| Spectrum | UVA / UVB / UVC / UVV |

| Filler | Gallium iodide |

| Material | US General Electric, Raesch Quartz Germany |

| End caps | Ceramic / metal ( more than 100 kinds) |

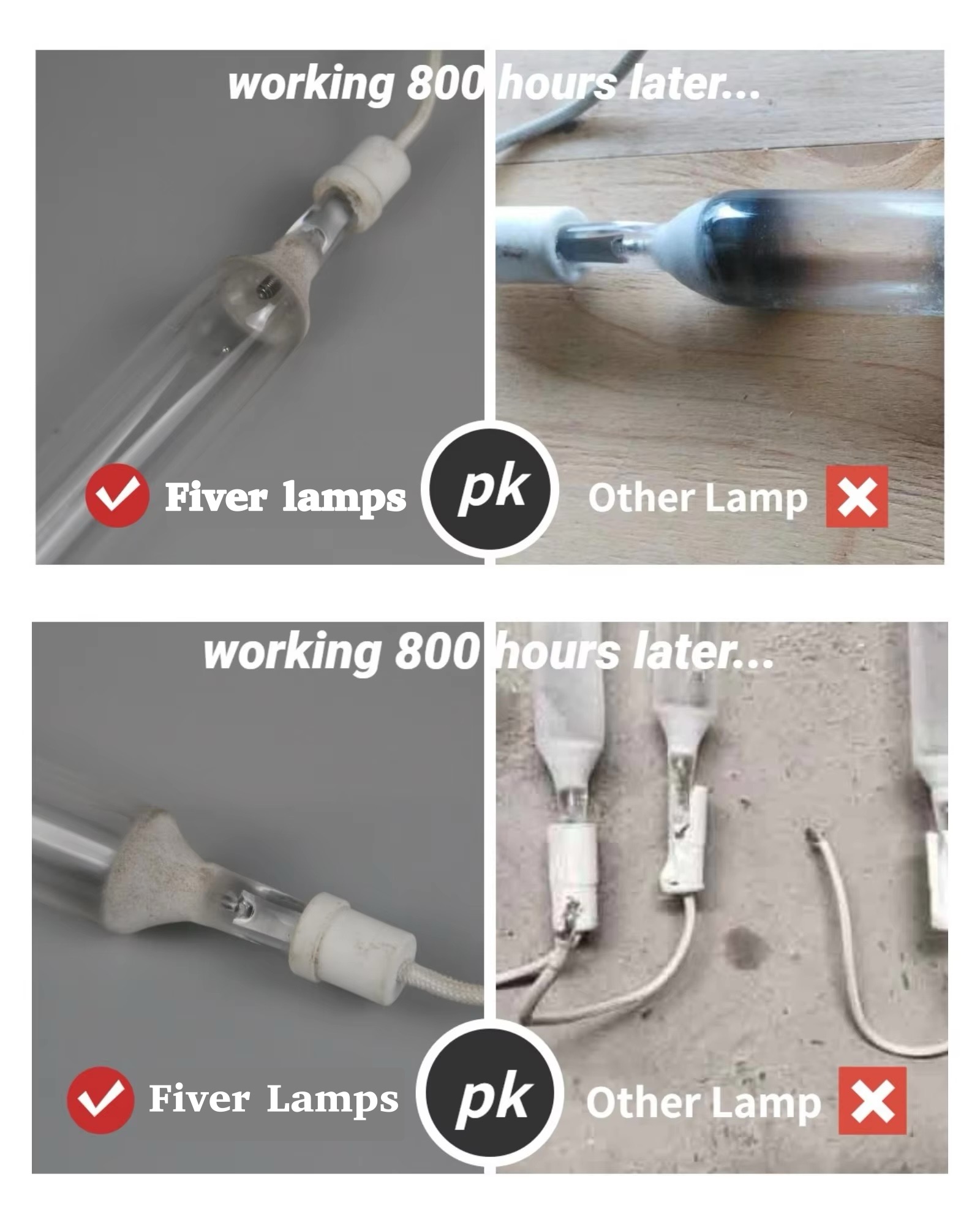

| Service life | 800 to 1000 hour |

Why Choose Iodine Gallium in Printing Industry?

Iodine Gallium lamps are a proven and reliable technology for UV curing in printing, offering a compelling balance of performance, cost-effectiveness, and established reliability. Their key advantages translate directly into tangible benefits for your business:

Powerful UVA Output for Efficient Curing: Our lamps emit a concentrated dose of UV radiation in the optimal UVA range (315-400nm), maximizing the curing efficiency of a wide range of UV-curable inks and coatings.

Rapid Curing for Increased Throughput: The high intensity of our Iodine Gallium lamps dramatically reduces curing times, allowing for faster production speeds and increased throughput, boosting your bottom line.

Instant On, Minimal Downtime: Unlike traditional mercury vapor lamps with lengthy warm-up periods, our Iodine Gallium lamps achieve full output instantly, minimizing downtime and maximizing productivity.

Proven Reliability for Consistent Results: With a long history of successful implementation in the printing industry, Iodine Gallium lamps offer consistent and reliable performance, ensuring consistent print quality batch after batch.

Specific Printing Applications of Iodine Gallium Lamp:

Screen Printing:

Stencil Creation (Exposure Units): Before the actual printing, a stencil is created on a mesh screen using a photosensitive emulsion. Iodine Gallium lamps are commonly used in exposure units to expose these screens. The high UVA intensity ensures a rapid and precise exposure, hardening the areas exposed to UV light and leaving the unexposed areas washable. This creates the printing stencil. The shorter exposure times compared to traditional methods increase production throughput.

Curing of UV Inks: While less common than in other printing methods, Iodine Gallium lamps can be used for curing UV inks directly on the substrate in some specialized screen printing applications. This is more prevalent when dealing with thicker ink films or specific ink formulations that are optimized for UVA curing.

Offset Lithography (Offset Printing):

Curing of UV Inks and Coatings: This is a major application. Offset printing often uses UV-curable inks and coatings for their fast drying times, high gloss, and superior rub and chemical resistance. Iodine Gallium lamps are integrated into offset presses to instantly cure these inks and coatings as the printed sheets exit the press. This allows for immediate further processing (e.g., cutting, folding, binding) without the need for drying time, significantly increasing production speed.

Specific Advantages in Offset: In offset, the ink film is relatively thin. The high intensity of Iodine Gallium lamps ensures efficient curing even with these thin films. The specific spectral output is also beneficial for certain types of offset inks and coatings.

Flexographic Printing (Flexo):

Curing of UV Inks and Coatings: Similar to offset, flexo printing increasingly uses UV-curable inks and coatings, especially in packaging applications. Iodine Gallium lamps can be used in flexo presses for inter-station curing (curing between color units) and final curing. This is particularly relevant for applications requiring high gloss, durability, and fast turnaround times.

Narrow Web Flexo: Iodine Gallium lamps are frequently used in narrow web flexo presses, which are used for printing labels, tags, and other narrow-format products.

Considerations and Comparisons When Using Iodine Gallium Lamp in Printing:

Ozone Generation: Like other mercury-based lamps, Iodine Gallium lamps generate ozone. Proper ventilation is essential.

Heat Generation: They generate heat, though generally less than traditional mercury arc lamps. Proper cooling is still required.

Lamp Degradation: UV output degrades over time, requiring regular monitoring and replacement.

Comparison to Mercury Arc Lamps: Iodine Gallium lamps offer a more focused UVA spectrum, instant start, and potentially longer lifespan.

Comparison to UV LEDs: UV LEDs offer better energy efficiency, longer lifespan, and more precise wavelength control. However, they can be more expensive, especially for large-area curing.

In summary, Iodine Gallium lamps play a crucial role in various printing processes by providing high-intensity UVA radiation for efficient curing of UV inks and coatings. Their cost-effectiveness and spectral characteristics make them a valuable tool for specific printing applications, particularly in screen, offset, and flexographic printing.

Why Choose Fiver Electronic Technology?

As a dedicated manufacturer, Fiver Electronic Technology is committed to providing high-quality, reliable, and truly tailor-made Iodine Gallium lamps for the printing industry. We offer:

Expert Consultation and Support: Our team of experienced engineers provides expert consultation and ongoing support, helping you select the perfect lamp for your unique application and ensuring seamless integration.

Custom Design and Manufacturing Capabilities: We have the in-house capabilities to design and manufacture custom lamps that precisely meet your specific requirements, no matter how complex.

Rigorous Quality Assurance for Unwavering Reliability: We adhere to stringent quality control standards throughout the manufacturing process to guarantee the consistent performance, reliability, and longevity of our products.

Contact us today to discuss your specific printing needs and discover how our custom Iodine Gallium lamps can optimize your production process and enhance your bottom line.