8KW UV Lights and Lamps for UV Cured Wood Finish

8KW UV Lights and Lamps for UV Cured Wood Finish

Product Parameters for Fiver's 8KW High Pressure Mercury UV Lamps

Lamp Power | 8KW |

Input Voltage | 380V |

| Lamp Current | 7.5A |

Arc Length | 1000 |

Total Length | 1100 |

Filler | Mercury / Metal halide / Gallium iodide |

Lamp Base | Optional |

Warranty | 1000 Hours |

Product Features for Our Lamp for UV Curing

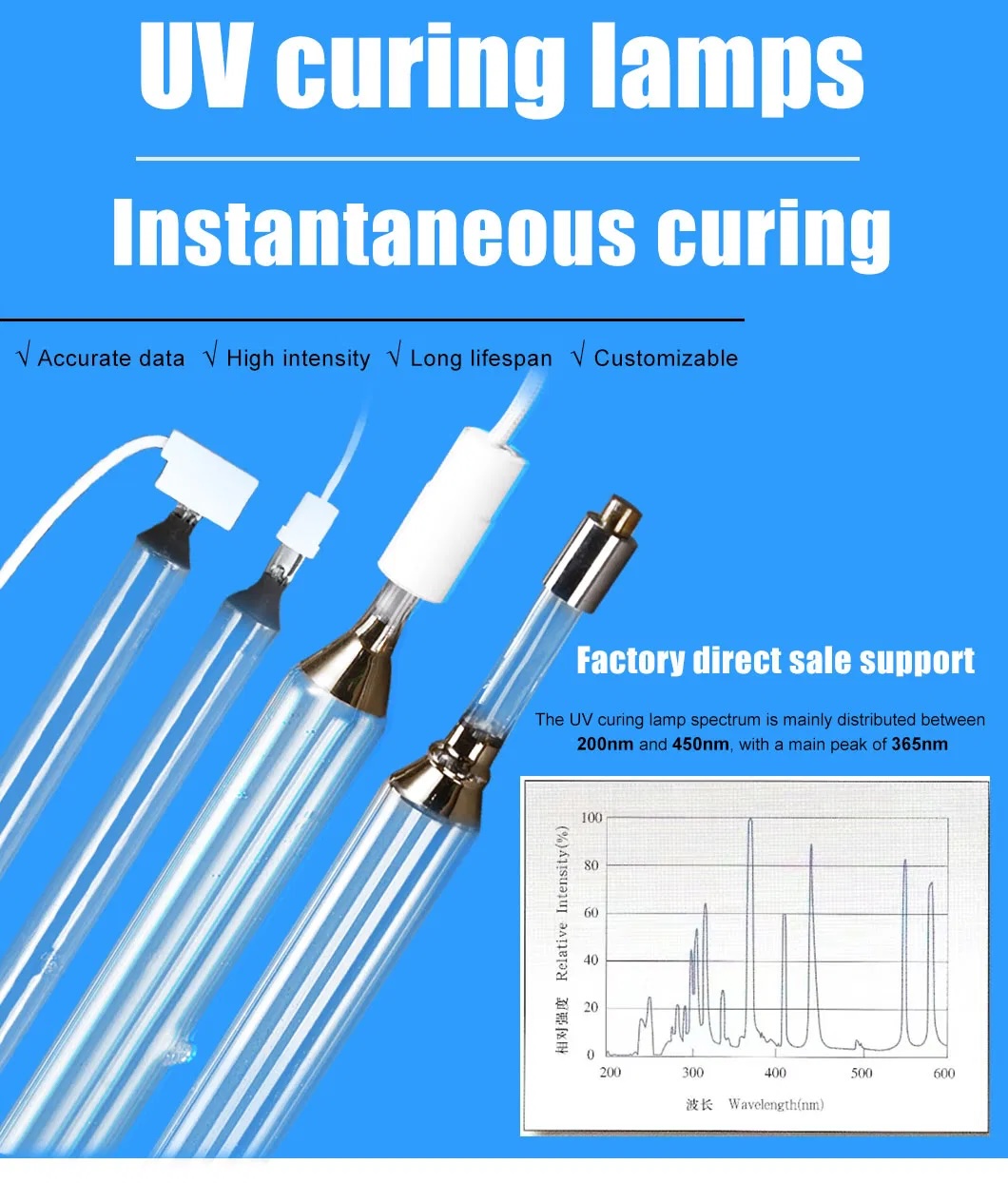

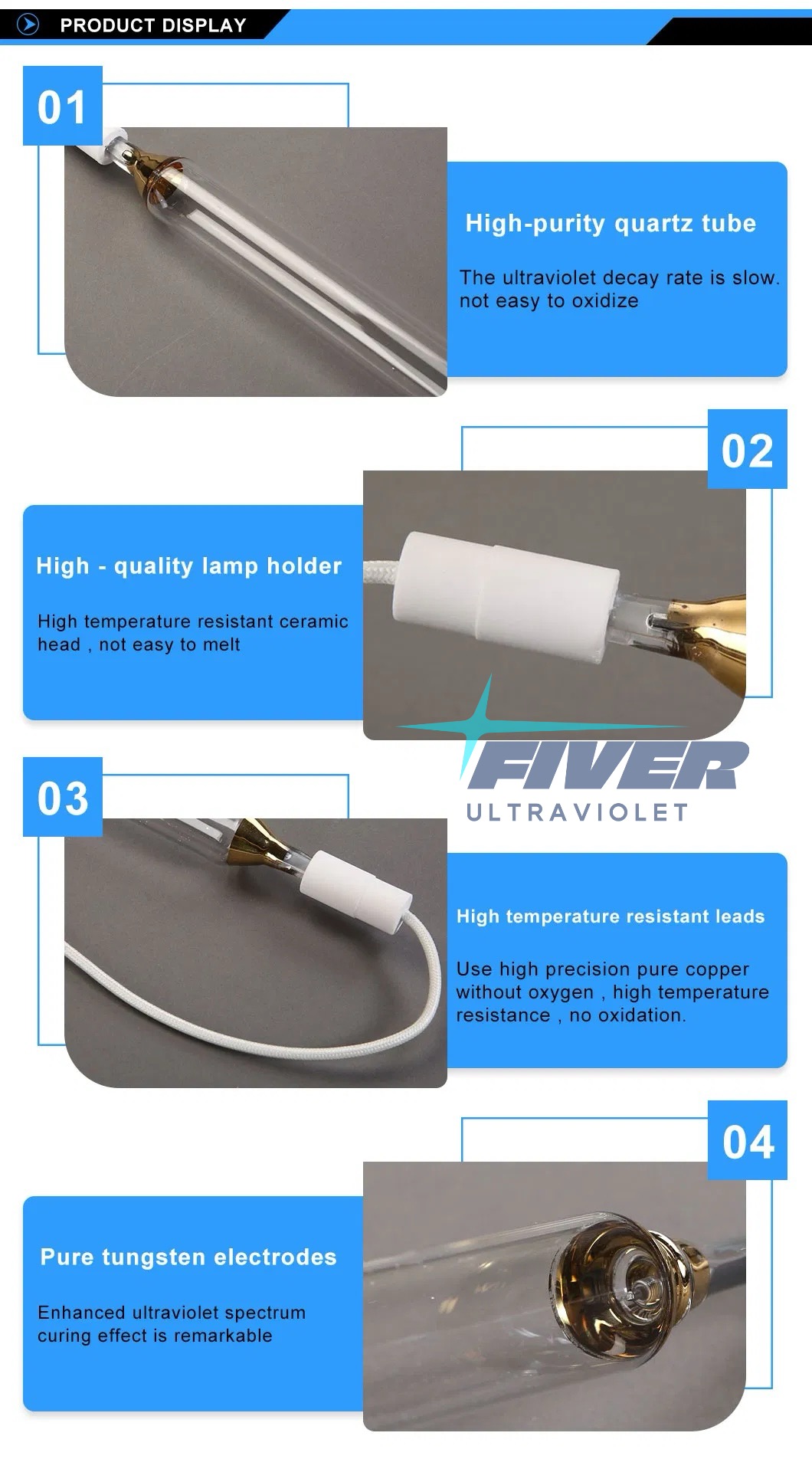

Fiver's UV lamps are manufactured in strict accordance with industry standards and technological levels, striving for the best in material selection, production, quality inspection, and packaging. We offer a variety of UV lamp models ranging from 200W to 20KW, all made of imported quartz tubes that have been tested and meet enterprise standards. Our lamps provide accurate data, high intensity, and long lifespan. Custom designs can be made according to user requirements.

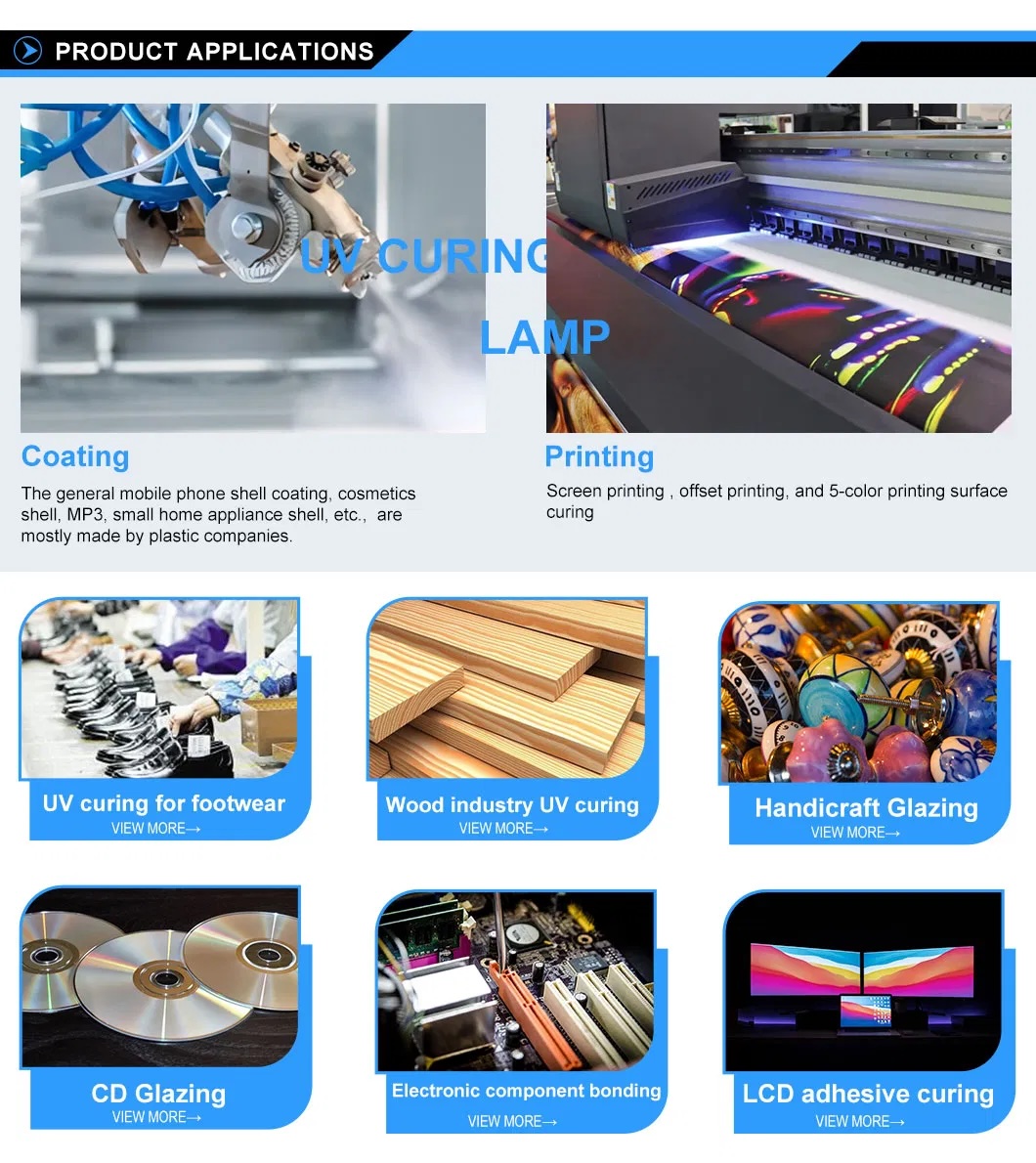

Applications of The UV Curing Lamps:

UV curing lamps have a wide range of applications across various industries due to their unique ability to quickly and efficiently cure UV - sensitive materials. such as Printing Industry, Woodworking and Furniture Industry, Automotive Industry, Electronics Industry,3D Printing and Additive Manufacturing...

Application of UV Curing In Wood Finishing:

UV (Ultraviolet) curing is a cutting-edge technology, that has revolutionized the wood finishing industry. By harnessing the power of UV light, this process offers numerous advantages over traditional methods, such as solvent-based and water-based finishes.

How UV Curing Works:

UV curing involves exposing a UV-sensitive coating to ultraviolet light. This triggers a photochemical reaction that instantly cures the coating, transforming it from a liquid to a solid state.

Benefits of UV Curing for Wood Finishing:

Rapid Curing: UV curing offers significantly faster curing times compared to traditional methods, leading to increased production efficiency.

Enhanced Durability: UV-cured finishes are known for their exceptional durability, resistance to scratches, and long-lasting performance.

Superior Finish: UV curing produces high-quality finishes with excellent gloss, clarity, and color retention.

Environmental Friendliness: UV curing processes often use low-VOC or VOC-free coatings, reducing environmental impact.

Energy Efficiency: UV curing systems are energy-efficient, minimizing energy consumption and reducing operating costs.

Applications of UV Curing in Wood Coating & Finishing:

Furniture: UV-cured finishes are widely used in furniture manufacturing, providing durable and attractive finishes for various wood surfaces.

Cabinetry:UV-cured coatings enhance the durability and appearance of kitchen and bathroom cabinets.

Flooring:UV-cured finishes protect wood floors from wear and tear, providing a long-lasting and beautiful surface.

Interior Trim:UV-cured coatings can be applied to interior trim, such as doors, windows, and molding, to improve their appearance and durability.

By adopting UV curing technology, wood finishers can achieve superior results while minimizing environmental impact.