220V 3KW UV Lamp Power Supply for UV Curing Machine

220V 3KW UV Lamp Power Supply for UV Curing Machine

UV lamp power supply also know as uv lamp ballast, is is an important part of ultraviolet/UV curing machine. Its main function is to provide stable current and voltage for uv curing lamps so that they can work normally and emit ultraviolet light to achieve the curing of materials

Brief Specifications for this 220V 3000W UV EPS

| Product Name | Intelligent uv ballast | Product brand | FIVER |

| Product Power | 3KW | Product model | FUV3KW-220V |

| Input Voltage (V) | 220V ac | Max Output Current (A) | 20A |

| Input Current (A) | 13.6/7.9A | Recommend Lamp Voltage | 200V |

| Output Voltage Range (V) | 150-230A | Cooling Method | Air Cooling |

( For more details please check the datasheet in PDF attachment)

Product Features for Fiver's 220V 3KW UV Ballast for UV Curing Lamps

1. Compact Design. This uv lamp power supply is small in size, saving installation space.

2. Soft Swithcing Function. our 3KW UV ballast for uv curing are with soft switching function, greatly reduce the impact of starting current, can greatly extend the uv lamp's lifespan.

3. Vector Algorithm, Fiver's UV EPS adpots the latest vector algorithm to ensure stable uv energy output.

4. High Voltage Triggering. Can drive various types of UV lamps (mercury lamps, metal halide lamps, iodine gallium lamps, and other special UV lamps).

5. Excellent Heat Dissipation. our uv power inverter are integrated intelligent inverter fan control to ensure appropriate heat dissipation and improve curing efficiency.

6. Various Communication Interfaces. Fiver's Intelligent UV variable frequency power supplies are with RS485 interface, and expansion for CANopen and Ethernet communication.

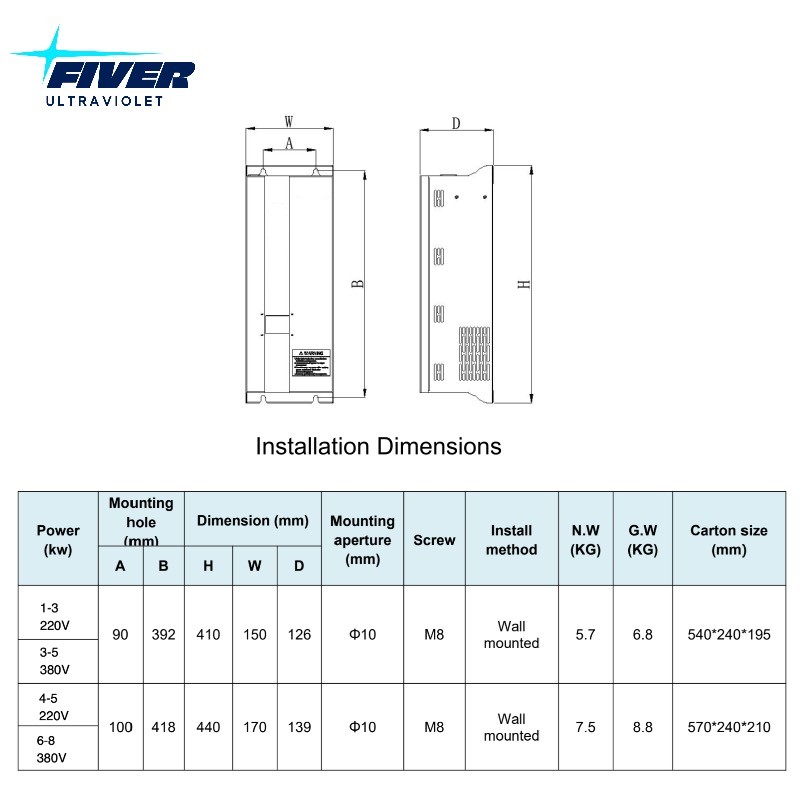

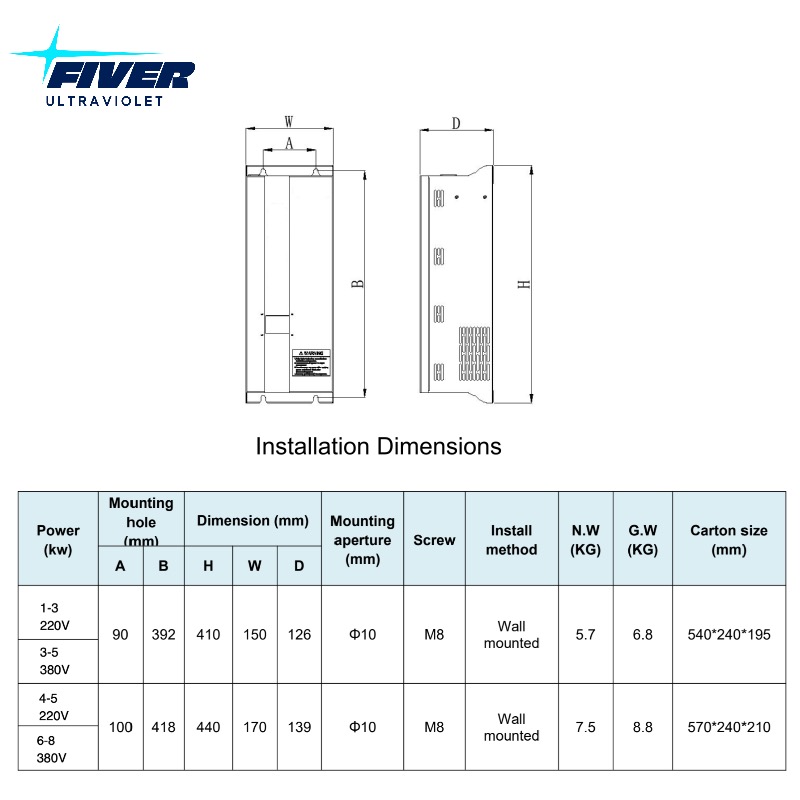

Installation Dimension for Fiver's 220V 3000W UV Lamp Power Supply

The Application Cases for the 3KW UV EPS for Curing UV Light:

Working Principle of Electronic UV Power Supply for UV Curing Lamps:

The working principle of the electronic ballast/electronic uv power supply for medium-pressure ultraviolet lamps is as follows:

I. Input power supply

Connect to an alternating current uv lamp power supply, generally mains power.

II. Rectification and filtering

1. Firstly, the alternating current power supply is converted into pulsating direct current power through a rectifier circuit (usually composed of diodes, etc.).

2. Then, through the filtering stage, components such as capacitors and inductors are used to filter out the ripples in the direct current to obtain a relatively smooth direct current voltage.

III. High-frequency inversion

1. Electronic switching elements (such as transistors, field-effect transistors, etc.) are used to convert the smooth direct current voltage into high-frequency alternating current voltage.

2. By controlling the conduction and turn-off time of electronic switching elements, the frequency and amplitude of the output high-frequency alternating current voltage can be adjusted.

IV. Starting the medium-pressure ultraviolet lamp

1. The high-frequency alternating current voltage is applied to the medium-pressure ultraviolet lamp to generate a high-voltage pulse to start the discharge process of the lamp.

2. Once the lamp is started, the electronic ballast will adjust the output to maintain the lamp in a stable working state.

V. Control and protection

1. The uv lamp power supply usually also contains a control circuit for monitoring the working state of the lamp, such as current, voltage, power, etc.

2. When abnormal conditions occur, such as overcurrent, overvoltage, overheating, etc., the protection circuit will act and cut off the power supply to protect the uv lamp and the Electronic UV Ballast itself.

In Brief, the electronic uv ballast/uv power supply processes the input alternating current through electronic components (such as inductors, capacitors, transistors, etc.) by rectification, filtering, and inversion, and converts it into high-frequency alternating current suitable for the operation of uv curing lamps. After the circuit is connected, the electronic uv ballast first provides a relatively high starting voltage to excite the gas discharge in the uv curing light tube and make the lamp tube start to emit light. After the lamp tube is started, the ballast then limits the current to a stable range to ensure the normal and stable operation of the uv curing lights in the uv curing equipment.