Factory Supply Lamp UV Light 9.6KW High Intensity UV Lamp for Automotive Industry

Factory Supply Lamp UV Light 9.6KW High Intensity UV Lamp for Automotive Industry

Product Features for our Lamp UV Light

Fiver Environment Group Ltd is a leading manufacturer of UV lamps in China, renowned for their exceptional performance and durability

Why Choose Our UV Light Curing Lamp?

Superior Quality: Our lamp uv light are crafted using premium materials, including high-purity quartz tubes that can withstand extreme temperatures and maintain excellent light transmission.

Advanced Manufacturing: Our state-of-the-art manufacturing processes ensure optimal performance and longevity. Each lamp undergoes rigorous testing to meet the highest quality standards.

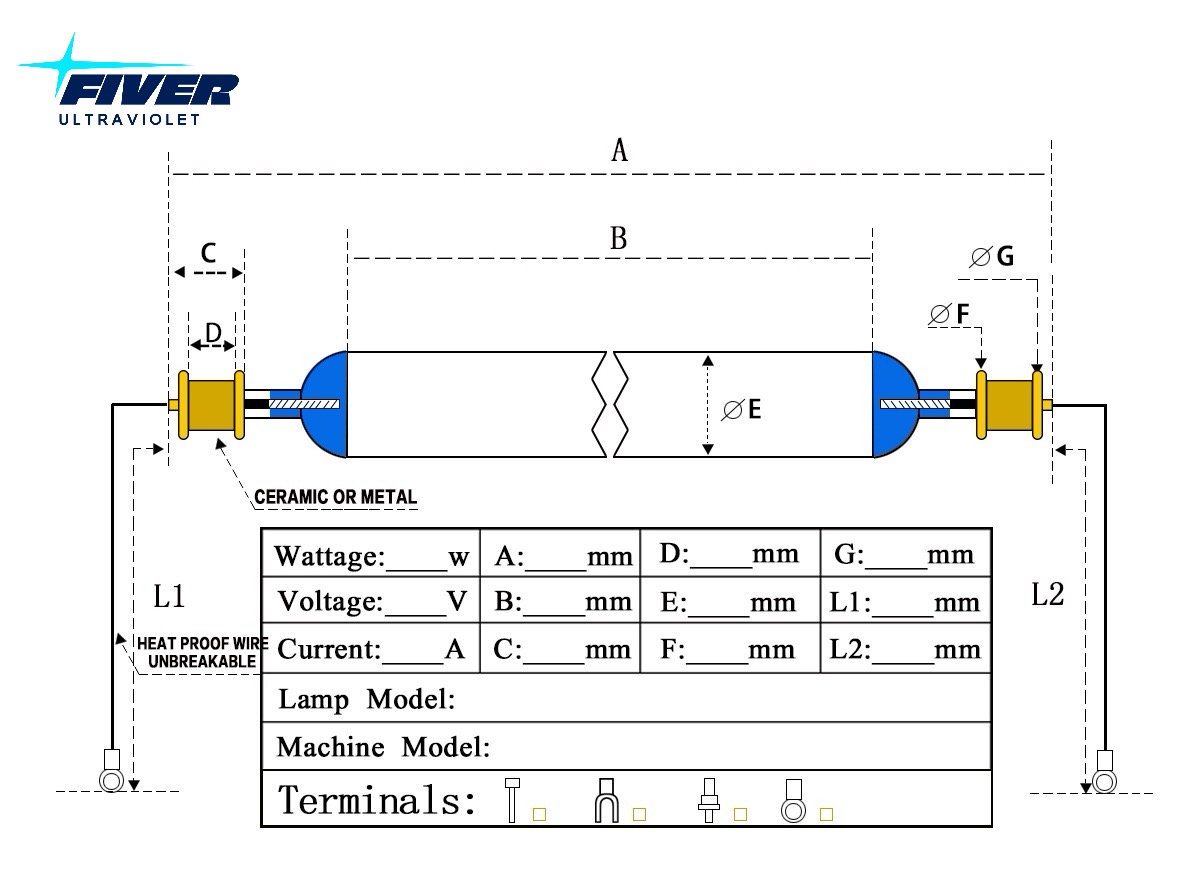

Customizable Solutions: We offer tailored solutions to meet your specific needs, including customization of lamp voltage, current, tube length, arc length, and filler materials.

Long Lifespan: Our UV lamps are designed for extended use, reducing maintenance costs and downtime.

Product Parameters for Fiver's 9.6KW UV Light Curing Lamp

Lamp Power | 9.6KW |

Input Voltage | 380V |

| Lamp Current | 7.5A |

Arc Length | 1250 |

Total Length | 1387 |

Filler | Mercury / Metal halide / Gallium iodide |

Lamp Base | Optional |

Warranty | 1000 Hours |

(We also provide customization service according to your needs)

How to Customize Your Automotive UV Curing Lamps?

If you have detailed lamp parameters please contact us directly Contact Us for UV Lamp Customization

We Fiver Environmeant Group is a professional manufacturer of variuos types UV curing lamps, we offer customization service for all our customers, Low MOQ, Short sead time, Professioanl sechnicial support.

| Parameter Range of UV Curing Lamps From Fiver | |

| Power output | 500w to 40kw |

| Wavelength | 320nm to 450nm |

| Arc length | 50mm to 2000mm |

| Pipe diameter | 18mm to 32mm |

| Power density | 30/60/80/120/160/200 w/cm |

| Spectrum | UVA / UVB / UVC / UVV |

| Filler | Mercury / Metal halide / Gallium iodide |

| Material | US General Electric, Raesch Quartz Germany |

| End caps | Ceramic / metal ( more than 100 kinds) |

| Service life | 800 to 1000 hour |

Applications of UV Curing In Automotive Painting Curing & Coating Finishing

High-intensity ultraviolet (UV) lamps play a crucial role in paint curing and coating finishing in the automotive industry. The following will introduce its working principle in detail.

I. Basic Working Principle of Ultraviolet Lamps

High-intensity ultraviolet (UV) lamps mainly achieve the curing of coatings by emitting ultraviolet rays with specific wavelengths. In the automotive industry, commonly used UV lamps usually generate ultraviolet radiation during the discharge process by utilizing mercury vapor or metal halides. When an electric current passes through the gas inside the lamp, the atoms and molecules in the gas are excited and brought into an excited state. When these excited atoms and molecules return to the ground state, ultraviolet photons will be released.

II. Specific Applications in Automotive Coating Curing

Initiating Chemical Reactions: Automotive coatings and painting usually contain photoinitiators. When irradiated by ultraviolet rays, photoinitiators absorb the energy of ultraviolet photons and generate active intermediates such as free radicals or cations. These active intermediates can initiate the polymerization reactions of monomers and oligomers in the coatings, thus enabling the coatings to cure rapidly. For example, in automotive refinishing paints, using ultraviolet-cured primers can greatly shorten the repair time and improve work efficiency.

Rapid Curing: Compared with traditional thermal curing methods, ultraviolet curing has the advantage of high speed. On automotive production lines, ultraviolet lamps can cure coatings within a few seconds, thus significantly improving production efficiency. For example, during the end-of-line assembly process of original equipment manufacturers (OEMs) in the automotive industry, UV curing lamps can be used to rapidly cure automotive parts to ensure the smooth operation of the production line.

Suitable for Small Area Repairs: In automotive body repair shops, for the repair of small area damages, usually referred to as "spot repairs", ultraviolet-cured primers can be used. This method can quickly repair small scratches and dents while maintaining the appearance quality of the vehicle.

III. Role in Coating Finishing

Improving Coating Performance: Ultraviolet curing can make coatings have better hardness, wear resistance and chemical resistance. This is because during the ultraviolet curing process, the molecules in the coatings can bind together more closely, forming a stronger network structure. For example, in the coating finishing of automotive wheels and bumpers and other components, using ultraviolet-cured coatings can improve the durability of these components.

Enhancing Appearance Effects: Ultraviolet-cured coatings can provide a smoother and more uniform surface, thus enhancing the appearance of the vehicle. In addition, ultraviolet-cured coatings can also achieve various special appearance effects, such as metallic luster and pearlescent effects, by adding special pigments and additives.

Environmental Protection and Energy Saving: The ultraviolet curing process does not require heating, so it can save energy and reduce carbon dioxide emissions. Meanwhile, ultraviolet-cured coatings usually do not contain volatile organic compounds (VOCs), which are more environmentally friendly.

In conclusion, high-intensity ultraviolet lamps play an important role in paint curing and coating finishing in the automotive industry through aspects such as initiating chemical reactions, rapid curing, improving coating performance, enhancing appearance effects, and being environmentally friendly and energy-saving. to learn more about How does ultraviolet curing coating enhance the appearance effect of cars?