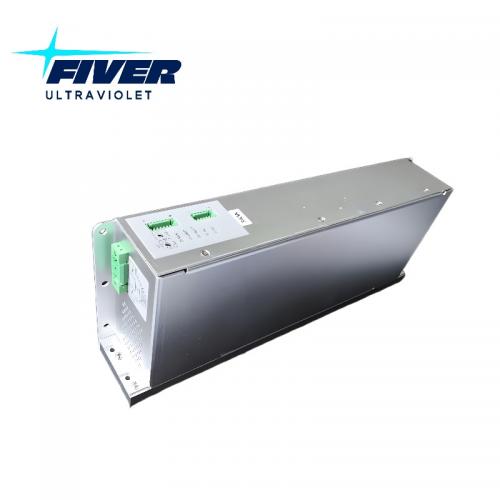

10KW UV Curing Light for Hardwood Floors

10KW UV Curing Light for Hardwood Floors

Product Features for Our Ultraviolet Light Lamp

1> High-Quality Materials: Utilizes premium components, including high-purity quartz tubes,pure tungsten electrode for stable maximum UV output and durability.

2> Durable Construction: Robustly built to withstand industrial environments and ensure long-term reliability.

3> Precise Wavelength Control: To optimize curing results, our ultraviolet curing light can be customized with specific fillers to achieve precise wavelength output, tailored to our customers' unique application requirements.

4> Long Lifespan: Designed for extended use, minimizing downtime and reducing maintenance costs. the promissed warranty is 800 to 1000 hours.

5>Customizable Options: As a uv curing light manufacturerur our ultraviolet light lamps available in various configurations to meet diverse application requirements.

Parameters for Fiver's 10KW UV Curing Light for Hardwood Floors

Lamp Power | 10KW |

Input Voltage | 380V |

| Lamp Current | 6.8A |

Arc Length | 1200 |

Total Length | 1350 |

Filler | Mercury / Metal halide / Gallium iodide |

Lamp Base | Optional |

Warranty | 1000 Hours |

(We offer customization service accoring to your needs, if you need customization please contact us)

| Parameter Range of UV Curing Lamps From Fiver | |

| Power output | 500w to 40kw |

| Wavelength | 320nm to 450nm |

| Arc length | 50mm to 2000mm |

| Pipe diameter | 18mm to 32mm |

| Power density | 30/60/80/120/160/200 w/cm |

| Spectrum | UVA / UVB / UVC / UVV |

| Filler | Mercury / Metal halide / Gallium iodide |

| Material | US General Electric, Raesch Quartz Germany |

| End caps | Ceramic / metal ( more than 100 kinds) |

| Service life | 800 to 1000 hour |

Applications of UV Curing Light for Hardwood Floors

UV curing light has revolutionized the process of hardwood floor finishing. UV curing for hardwood floors is a process using ultraviolet light to instantly harden floor finishes. Its unique properties offer a fast, efficient, and high - quality alternative to traditional curing methods. UV curing offers significant advantages over traditional methods for finishing hardwood floors.

1. Speed and Efficiency:

Rapid Curing:UV curing technology drastically reduces drying times compared to traditional solvent-based or water-based finishes. This translates to faster project completion, reduced labor costs, and increased productivity for flooring contractors.

Reduced Downtime: The rapid curing process minimizes downtime, allowing homeowners to use their newly finished floors sooner.

2. Enhanced Durability and Performance:

Superior Hardness: UV-cured finishes exhibit exceptional hardness and resistance to scratches, scuffs, and wear and tear. This results in floors that are more durable and require less maintenance over time.

Improved Scratch Resistance: The increased hardness provides superior protection against daily wear and tear, such as pet scratches, furniture scuffs, and high-traffic areas.

3. Environmental Benefits:

Reduced VOC Emissions: UV curing often utilizes low-VOC or even VOC-free finishes, minimizing harmful emissions and creating a healthier indoor environment for homeowners.

Eco-Friendly Process: By minimizing drying times and reducing the use of solvents, UV curing contributes to a more sustainable and environmentally friendly flooring process.

4. Enhanced Aesthetics:

Improved Finish Quality: UV curing often results in a smoother, more uniform finish with enhanced gloss and clarity, enhancing the overall appearance of the hardwood floor.

UV curing offers a compelling alternative to traditional finishing methods for hardwood floors. By providing faster curing times, enhanced durability, improved aesthetics, and reduced environmental impact, UV curing technology delivers a superior finish while increasing efficiency and sustainability.