Tailored 417nm UV Exposure Lamp for Printing Plate Making

Tailored 417nm UV Exposure Lamp for Printing Plate Making

In the demanding world of printing, precise and efficient plate making is paramount. Our tailored 417nm UV Exposure Lamps provide the high-intensity, focused UV light necessary for creating high-resolution printing plates, ensuring superior print quality and faster production times.

Why 417nm UV Light for Plate Making?

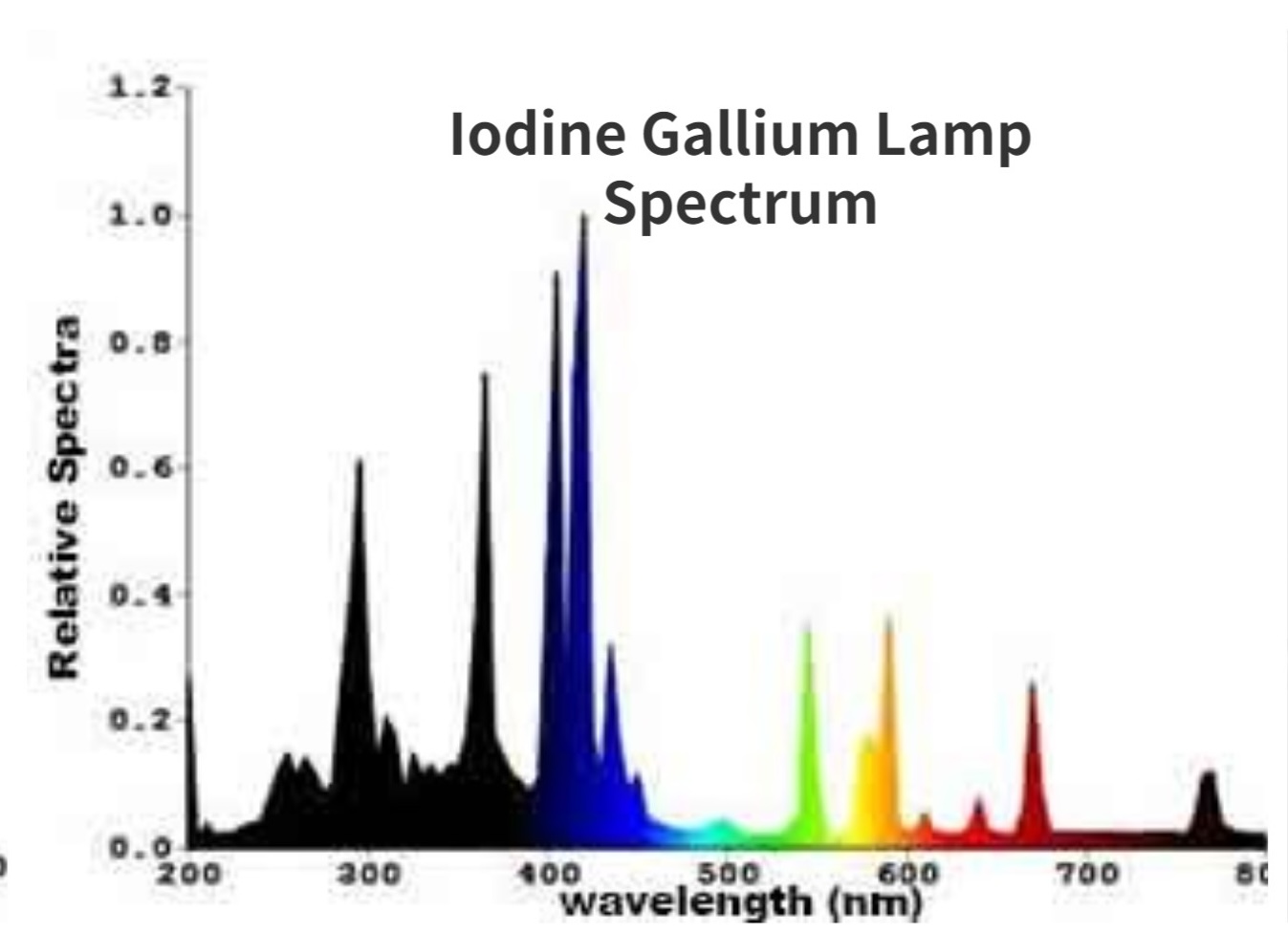

The 417nm wavelength falls within the optimal absorption range of many photopolymers used in plate making. This precise spectral match results in efficient energy transfer, leading to several key advantages:

Optimal Spectral Matching: Our 417nm UV Exposure Lamp is specifically designed to align with the peak sensitivity of common photopolymers, maximizing curing efficiency.

Faster Exposure Times: Efficient energy transfer means shorter exposure times, boosting your plate-making throughput and overall production speed.

High Resolution and Detail: The precise exposure provided by our 417nm UV light exposure lamp enables the reproduction of fine lines, small dots, and intricate details on the printing plate, resulting in sharper and more accurate printed images.

Custom-Engineered UV Plate Exposure Lamp Solutions

At Fiver, we understand that every plate-making setup is unique. That's why we offer tailored solutions:

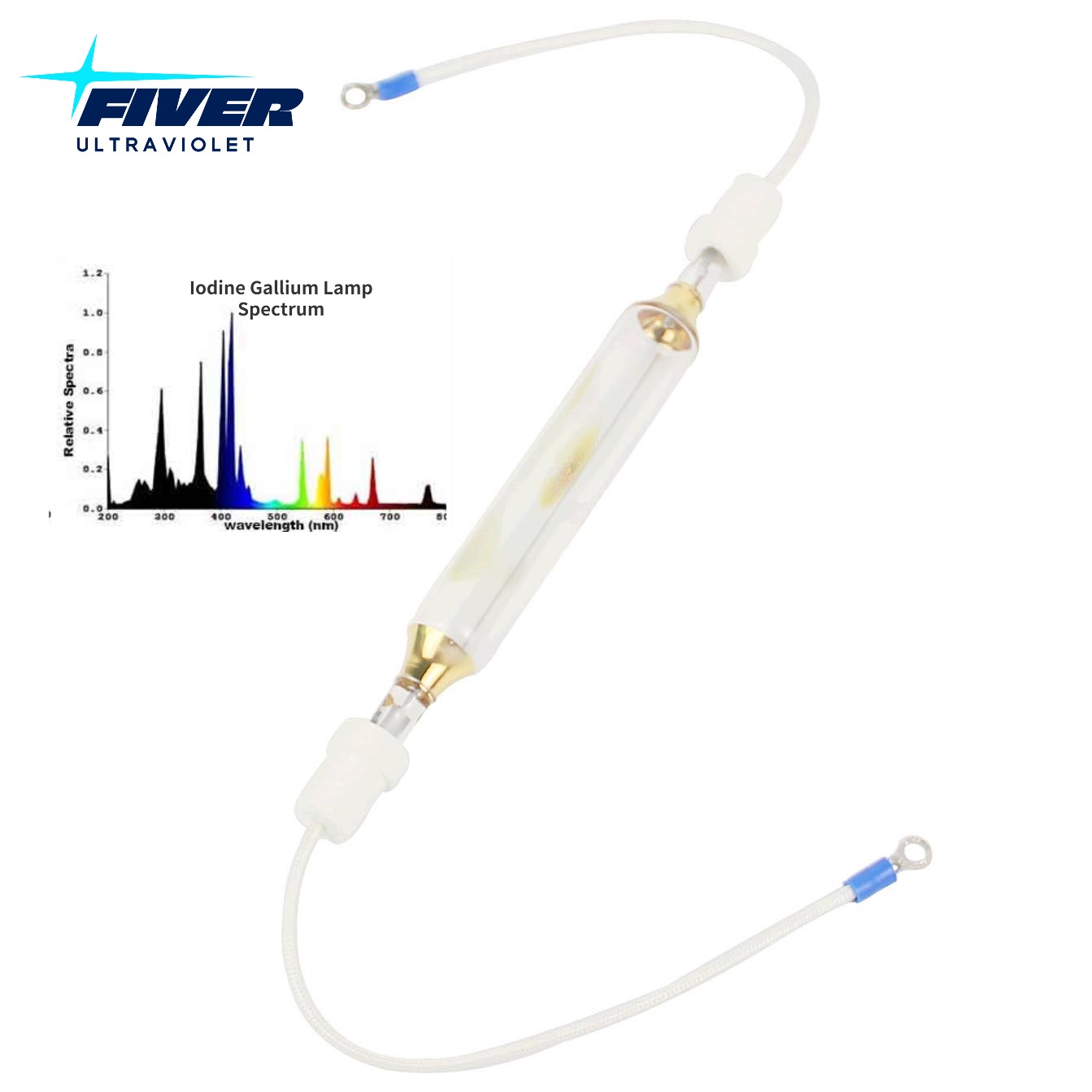

Custom Lamp Length and Design: We engineer custom lamp lengths and designs to ensure uniform UV coverage across various plate sizes and exposure units, guaranteeing even curing and eliminating inconsistencies.

Intensity Control: Our UV light exposure lamp systems offer precise intensity control, allowing you to fine-tune exposure times and prevent overexposure, ensuring optimal plate quality.

| Parameter Range of UV Curing Lamps From Fiver | |

| Power output | 500w to 40kw |

| Wavelength | 320nm to 450nm |

| Arc length | 50mm to 2000mm |

| Tube diameter | 18mm to 32mm |

| Power density | 30/60/80/120/160/200 w/cm |

| Spectrum | UVA / UVB / UVC / UVV |

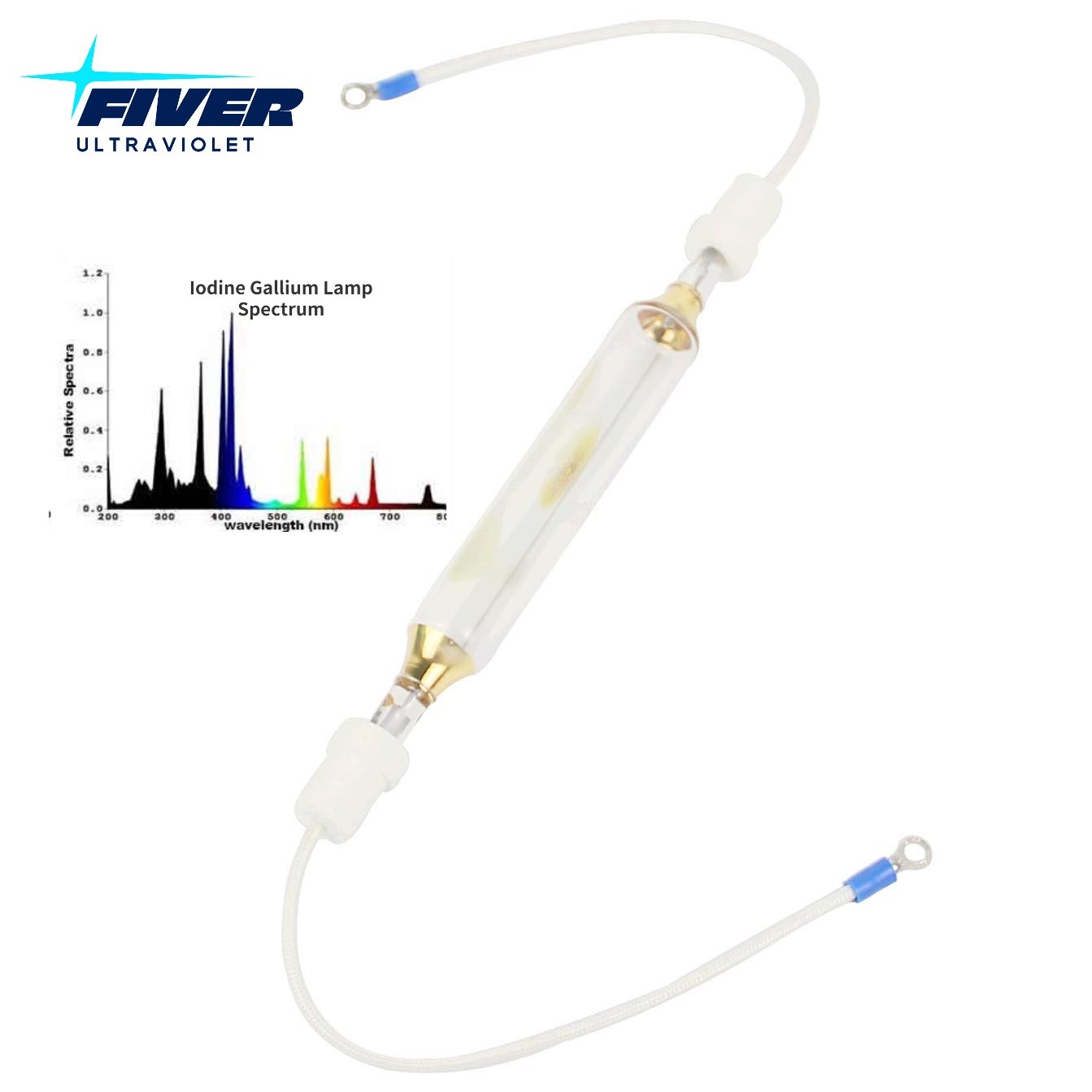

| Filler | Mercury / Metal halide / Gallium iodide |

| Material | US General Electric, Raesch Quartz Germany |

| End caps | Ceramic / metal ( more than 100 kinds) |

| Service life | 800 to 1000 hour |

Contact our sales team to customze: jerry@fiveruvc.com

Versatile Applications in Printing Plate Making

Our 417nm UV Exposure Lamps are ideal for various plate-making applications:

Offset Lithography: Whether you're using traditional film exposure or modern Computer-to-Plate (CtP) systems, our UV plate exposure lamp solutions provide the precision and efficiency needed for high-quality offset printing.

Flexographic Printing: Our lamps are also suitable for exposing photopolymer plates used in flexographic printing, ensuring accurate and consistent image transfer.

Silk Screen Exposure Light: For screen printing, our 417nm UV Exposure Lamp is an excellent choice for exposing photosensitive emulsions, creating high-resolution stencils for sharp and detailed prints.

Fiver Electronic Technology: Your Trusted Partner in UV Exposure

As a dedicated manufacturer of UV Exposure Lamps, we are committed to providing high-quality, reliable solutions:

Manufacturing Capabilities: Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure the performance and reliability of every UV light exposure lamp we produce.

Technical Support and Consultation: Our team of experienced engineers provides expert consultation and ongoing support to help you select the right UV Exposure Lamp for your specific plate-making needs.

Experience and Track Record: With years of experience in the UV industry, we have a proven track record of providing innovative and reliable UV solutions to printing businesses worldwide.