Custom 396nm UV Curing Lamps for Offset Printing | FIVER UV Technology

Custom 396nm UV Curing Lamps for Offset Printing

Precision. Performance. Sustainability.

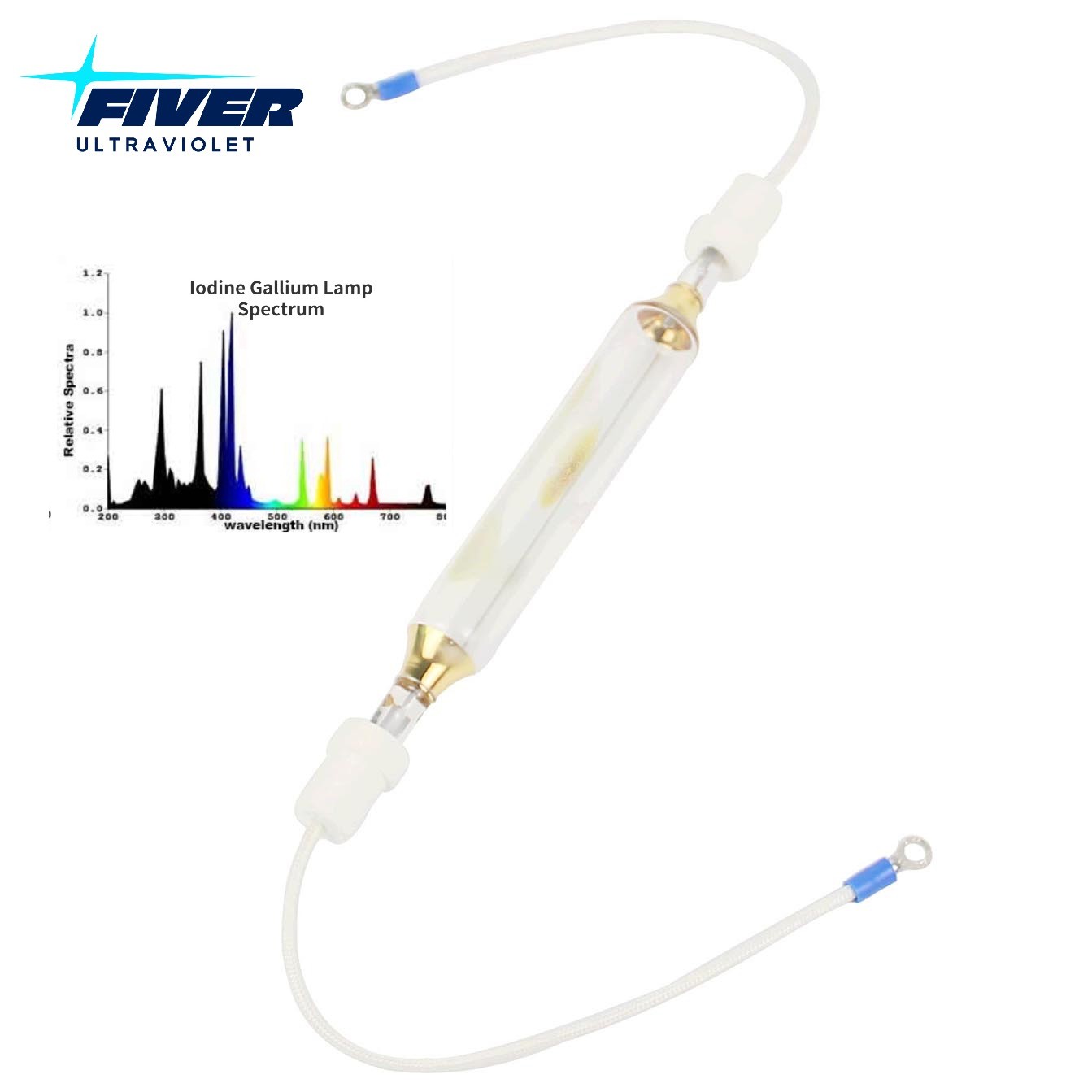

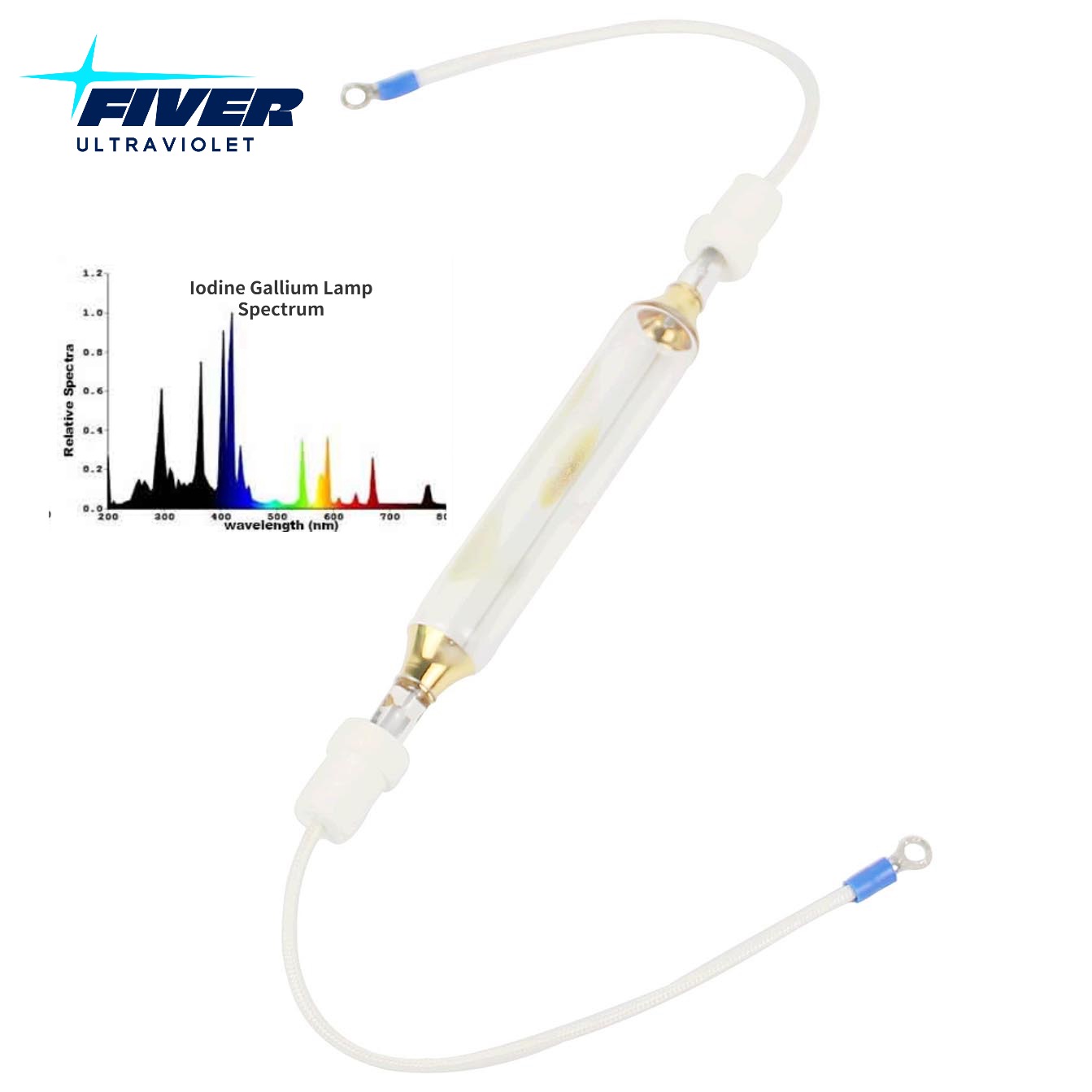

At FIVER UV Technology, we specialize in engineering advanced UV curing solutions tailored to the exacting demands of modern offset printing. Our custom 396nm UV curing lamps are designed to deliver unmatched spectral precision, energy efficiency, and eco-friendly performance, empowering printers to achieve faster production speeds, sharper details, and compliance with global sustainability standards.

Why Choose FIVER’s 396nm UV Lamps?

1. Spectral Precision for Superior Curing

396nm UVA Wavelength: Perfectly aligned with the absorption peaks of UV offset inks and coatings, ensuring rapid polymerization of thin layers and fine details.

Consistent Output: Eliminates under-curing or over-curing risks, even for high-resolution halftones and metallic finishes.

2. Tailored to Your Workflow

Fully Customizable:

Power Density: Adjust from 120 W/cm² to 240 W/cm² for high-speed presses (15,000+ sheets/hour).

Lamp Dimensions: Designed to fit narrow-web, sheet-fed, or hybrid offset systems.

Cooling Systems: Choose air- or water-cooled configurations to protect heat-sensitive substrates like coated paper, films, or foils.

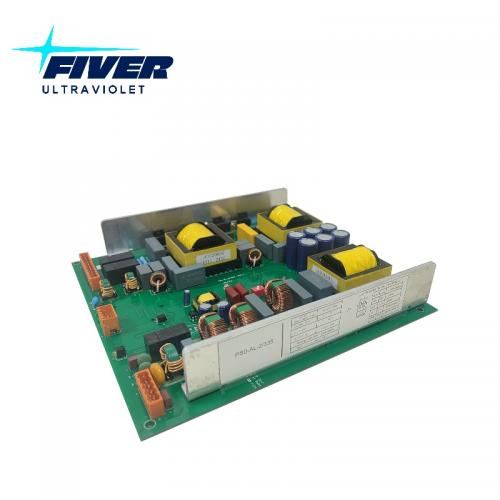

Retrofit Kits: Upgrade existing mercury-based systems seamlessly.

3. Eco-Friendly & Compliant

Mercury-Free Design: Aligns with RoHS, REACH, and FDA regulations—ideal for food, pharma, and consumer packaging.

Low Heat & Ozone Emissions: Reduces energy costs and eliminates the need for ozone exhaust systems.

4. Unbeatable Efficiency

30% Energy Savings: Advanced electrical-to-UV conversion outperforms traditional mercury lamps.

Extended Lifespan: 2,000–3,000 hours of reliable operation with minimal maintenance.

Applications

Our 396nm UV lamps are trusted by industry leaders for:

Premium Packaging: Folding cartons, luxury cosmetic boxes, and pharmaceutical blister packs.

Commercial Printing: High-gloss brochures, catalogs, and magazines.

Labels & Security Printing: Tamper-evident labels, holographic foils, and banknote features.

Hybrid Coatings: Tactile varnishes, metallic effects, and scratch-resistant finishes.

Technical Advantages

Feature | FIVER 396nm Lamp | Standard Mercury Lamps |

Wavelength | 396nm (UVA-optimized) | Broad spectrum (254nm + 365nm) |

Heat Output | Low | High |

Compliance | Mercury-free, RoHS/REACH | Contains mercury |

Lifespan | 2,000–3,000 hours | 800–1,500 hours |

Customization | Fully tailored | Off-the-shelf |

Case Study: Revolutionizing Luxury Packaging

Client Challenge: A premium cosmetics brand needed to cure UV coatings on foil-laminated boxes without warping or yellowing.

FIVER Solution:

Custom 396nm lamps with low-heat output and instant on/off functionality.

Spectral tuning to match specialty metallic inks.

-----Results:

40% faster production speeds.

Zero substrate damage and 50% lower energy costs.

Compliant with EU food-contact regulations.

Why Partner with FIVER UV Technology?

Decades of Expertise: Our engineers optimize lamp performance for your inks, substrates, and press configuration.

End-to-End Support: From spectral analysis to installation and maintenance.

Future-Proof Compliance: Stay ahead of global environmental regulations.

Request Your Custom Solution Today

Upgrade to FIVER’s 396nm UV lamps and experience:

✅ Crisper details and vibrant colors.

✅ Faster turnaround with energy savings.

✅ Sustainable production without compromise.