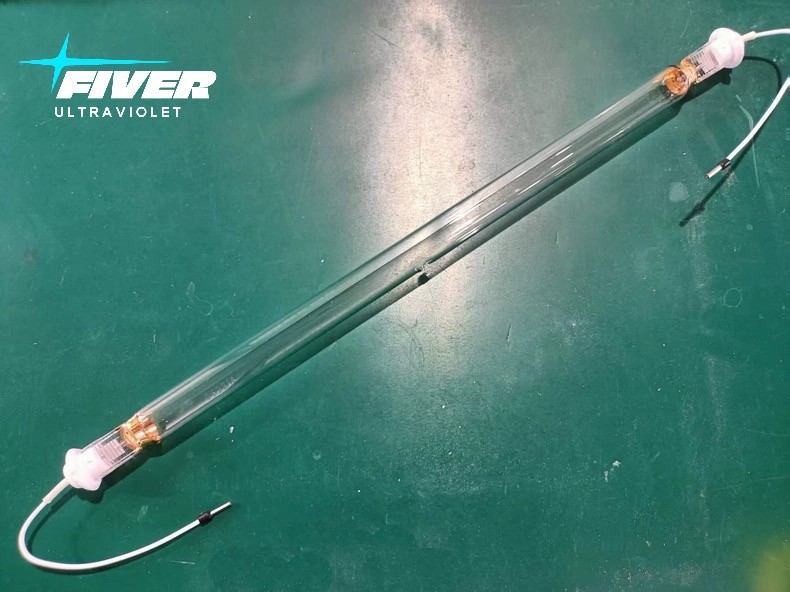

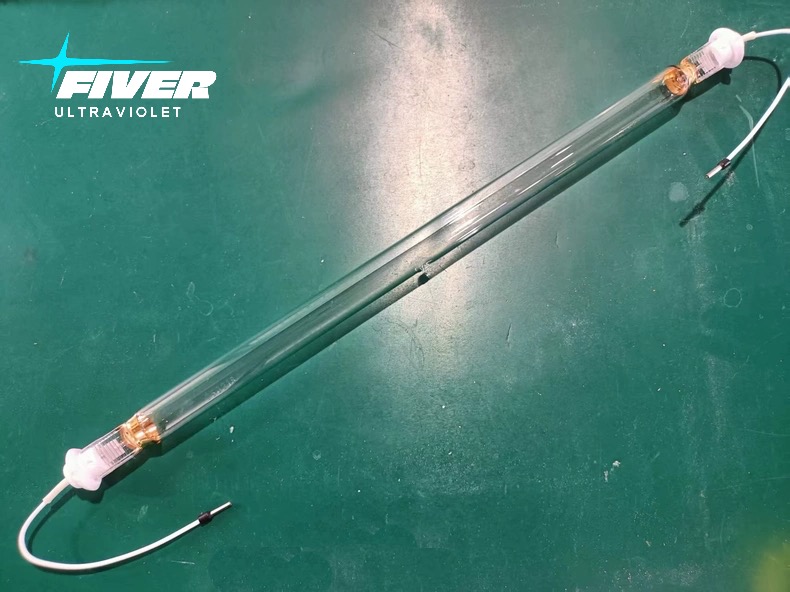

Panasia 435mm 3500W UV Lamp Replacement for Gloen-Patrol Ballast Water Treatment

435mm 3500W UV Lamp Replacement for Panasia Gloen-Patrol Ballast Water Treatment

Maintain the disinfection efficacy and regulatory compliance of your Panasia Gloen-Patrol Ballast Water Treatment System with our quality & cost effective replacement UV lamp. This high-precision Gloen PUL3.5_1 UV lamp is engineered to exact OEM specifications, delivering the required 3500W ultraviolet dose to effectively inactivate aquatic invasive species in ballast water. As a critical component of your Ballast Water Management System, using a quality replacement ensures uninterrupted operation and protects your vessel's compliance with IMO and US Coast Guard standards.

Product Features of Fiver's Panasia Gloen PUL3.5_1 UV Lamp Replacement

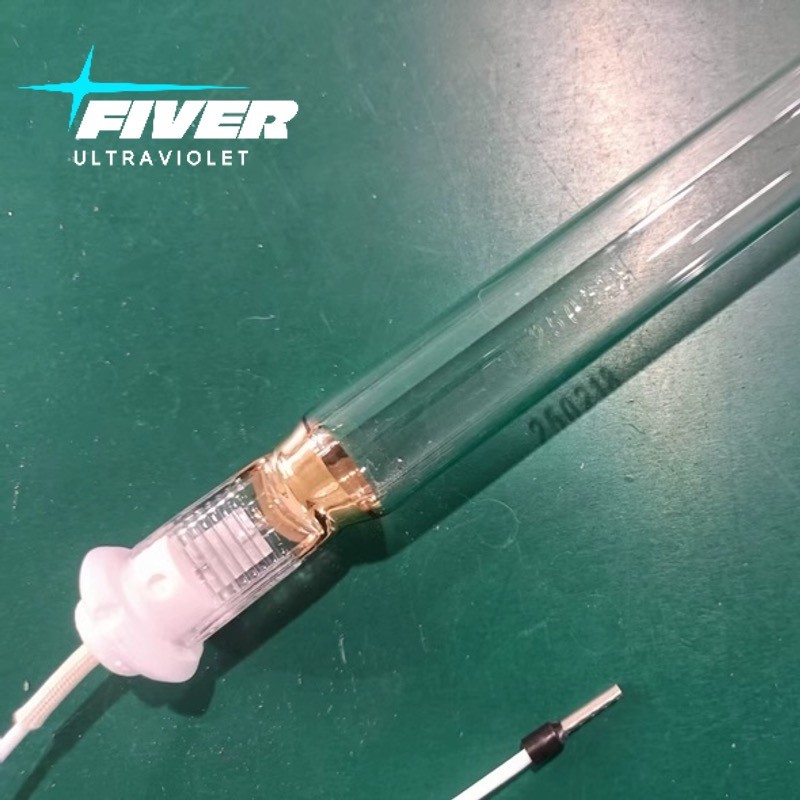

1> Precise OEM Compatibility: This lamp is designed as a direct-fit replacement for the Panasia Gloen-Patrol UV Lamp, ensuring perfect compatibility with the Gloen-Patrol BWTS housing and electrical systems. No modifications are required for a seamless installation. we also offer different terminals for different installation needs.

2> Optimal 3500W UV-C Output: Generates the exact intensity of ultraviolet light (254nm) needed to achieve the mandated biological efficacy, safeguarding your vessel against compliance issues related to under-dosing.

3> Long-Lasting Durability: Manufactured with high-quality quartz glass and robust electrodes to withstand the demanding marine environment, useful lifespan up to 4000 hours maximizing service life and reducing total cost of ownership.

4> Maintain System Integrity: Regular replacement of Ballast water treatment UV lamps is essential for maintaining the designed UV transmittance (UVT) and ensuring the entire Ballast Water Management System functions as intended.

5> Supported by Experts: Our technical team understands the Gloen-Patrol system intimately, providing support to ensure you select the correct components and maintain your system effectively.

Parameters of Fiver's Panasia 435mm 3500W UV Lamp Alternatives:

| Lamp Type | Medium Pressure UV Lamp |

| Part Number | Gloen PUL3.5_1 |

| Power | 3.5KW |

| Total Length | 435mm |

| Quartz Type | Regular |

| UV System Model | Panasia Gloen-Patrol BWTS |

| Warranty Time | 4000 Hours |

Maintenance Procedures & Notes for the Panasia Gloen-Patrol BWTS

I. Basic Characteristics & Core Function

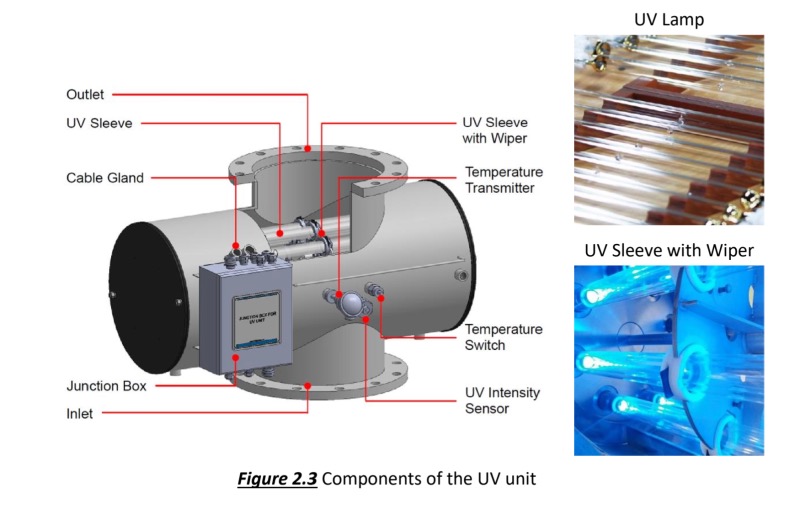

Lamp Type & Principle: The Panasia Gloen-Patrol system Utilizes Medium-Pressure Ultraviolet (MPUV) lamps, which emit broad-spectrum, high-intensity UV light to destroy the DNA of organisms smaller than 50µm (such as algae, bacteria, viruses) and pathogens in ballast water. This prevents their reproduction and colonization, ensuring discharged water complies with the IMO D-2 standard and USCG regulations.

Installation Requirements: Regardless of whether the UV Chamber is installed vertically or horizontally, the UV lamps must be positioned horizontally. Each lamp is enclosed within a Quartz Sleeve, featuring a waterproof seal design to prevent direct contact between the lamp and the water.

System Compatibility: Specifically designed for the Panasia Gloen-Patrol series Ballast Water Management System (BWMS). It is compatible with both standard UV Chambers (e.g., PU50, PU250, PU500) and explosion-proof models (PU###-Ex), serving as the core disinfection component in the "Filtration + UV Disinfection" process.

II. Maintenance Procedures

Regular Inspection & Cleaning

Quartz Sleeve Cleaning: Although an automatic wiper system is present, manual inspection is periodically required. If UV intensity consistently remains below the setpoint (e.g., 93 mW/cm²), power must be disconnected, the chamber drained, and the outer wall of the quartz sleeves wiped with alcohol to remove scale or organic residue.

UV Intensity Sensor Calibration: The sensor must be calibrated annually using a UV reference radiometer (e.g., MUV 2.4 WR). If the deviation between the measured value and the sensor reading exceeds ±5%, the sensor needs replacement.

Lamp Replacement Steps (Refer to Manual Table 7.3) HOW TO REPLACE THE UV LAMP FOR PANASIA GLOEN PATROL BWTS?

1>Turn off the BWMS main power and the UV power panel circuit breaker. Ensure the lamp is de-energized and cooled (for at least 5 minutes).

2> Remove the end covers from both sides of the UV chamber. Unscrew the lamp base plate screws (6x M4) and disconnect the lamp wire connectors.

3> Remove the spring and anti-vibration washer from inside the quartz sleeve, then remove the old lamp.

4> Wearing clean, powder-free gloves (to avoid fingerprint contamination), install the new lamp (Model PUL3.5_1). If the lamp is soiled, clean it with an alcohol wipe.

5> Reassemble in the reverse order of disassembly. After powering on, use "Check Mode" to verify the lamp lights up normally.

Fault Detection

A UV lamp test kit (ABS material, input voltage 110/220V) is provided for quick onboard lamp testing: Clamp the fixture onto the lamp's center bolt or O-terminal, press the test button. A green light indicates a good lamp; a red light indicates a faulty lamp.

Safety Regulations

UV Radiation Protection: Operating UV lamps emit high-intensity ultraviolet radiation. Direct exposure can damage eyes and skin. Operators must wear protective goggles. Never look directly at an illuminated UV lamp without protection.

High-Temperature Protection: Lamp surface temperature during operation can reach 600°C–800°C. Ceramic holders also retain high heat. Allow a 5-minute cooling period before touching or disassembling components.

Mercury Contamination Prevention: UV lamps contain trace amounts of mercury. Store them in their original packaging until use. If a lamp breaks, immediately collect the fragments using a sealed container to prevent mercury vapor release. Do not dispose of as regular waste (must be handled according to local environmental regulations).

Explosion-Proof Requirements: Lamps for explosion-proof UV Chambers (PU###-Ex) are identical to standard models. However, the power supply wiring must use intrinsically safe cables, maintaining a minimum distance of ≥50mm from standard cables.