40KW Electronic UV Light Power Supplies for Wood Product Curing and Coating

40KW Electronic UV Light Power Supplies for Wood Product Curing and Coating

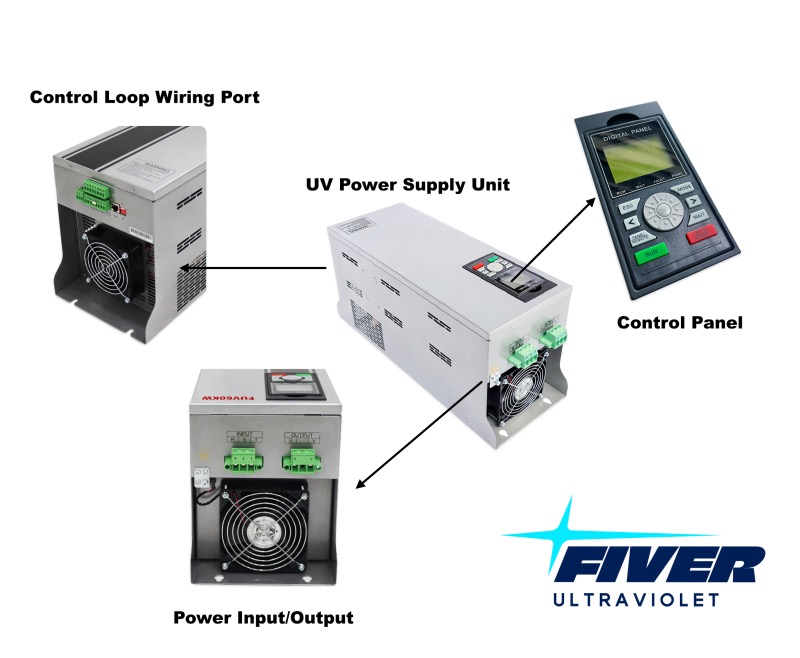

Brief Parameters for the 40KW UV Light Power Supply

| Product Name | Intelligent uv ballast | Product brand | FIVER |

| Product Power | 40KW | Product model | FUV40KW |

| Input Voltage (V) | 360-480V ac | Max Output Current (A) | 17A |

| Input Current (A) | 60.8A | Lamp Operating Voltage | 3000V |

| Output Voltage Range (V) | 2850-3050 | Cooling Method | Air Cooling |

( For more details please check the datasheet in PDF attachment)

Product Featueres for this Smart UV Power Supply

1. Wide voltage adaptability, Fiver's 40KW uv light power supply can operate normally with input voltage of 360V-480V.Different regions and countries may have varying voltage standards. A device with wide voltage adaptability can be used in multiple locations without the need for additional voltage converters or adapters. what's more it can withstand these fluctuations and operate reliably under different voltage conditions. Eliminating the need for additional voltage converters or adapters can save costs for users and reduce the complexity of the setup process.

2. Fast dynamic response speed, Our smart uv power supply only takes 500ms from standby to full power output. Devices with fast dynamic response speed can improve user experience by delivering quick and responsive feedback. This can be particularly important for uv curing systems. Fast dynamic response speed helps maintain system stability by minimizing delays in responding to changes. This is crucial in applications where stability is critical, such as in power electronics or control systems. Faster response times can also contribute to energy efficiency by optimizing the performance of the device and reducing unnecessary energy consumption.

3. Stepless Dimming. Fiver's uv high frequency power supply can Infinitely adjustable output power from 10% to 100% with smooth dimming, and the standby power can operate stably for a long period.

4. Independent air duct design, Our uv mercury lamp power supply effectively isolating components and pollutants, ensuring the power supply can operate in harsh environments for a long period.

5. Excellent heat dissipation, High Overload Capacity. This 40KW UV ballast, Integrated variable frequency fan control function, intelligently controlling the ventilation. enhancing the product's overload capacity..

6. LCD Operation Panel. Fiver's uv power supply units integrated LCD control panel, easy for operation.

7. Self-resonant Technology. Our uv stepless power supply utilizing self-resonant technology, by optimizing parameters, higher excitation voltage is achieved, making lamp ignition easier.

8. UV Light Intensity Detection. The addition of energy detection functionality allows for light intensity collection, alarm triggering when light intensity exceeds set values, and enables closed-loop control of light intensity.

9. Multipal Communication Interface. Standard RS485 communication interface, supporting Modbus RTU protocol.and expansion for CANopen and Ethernet communication.

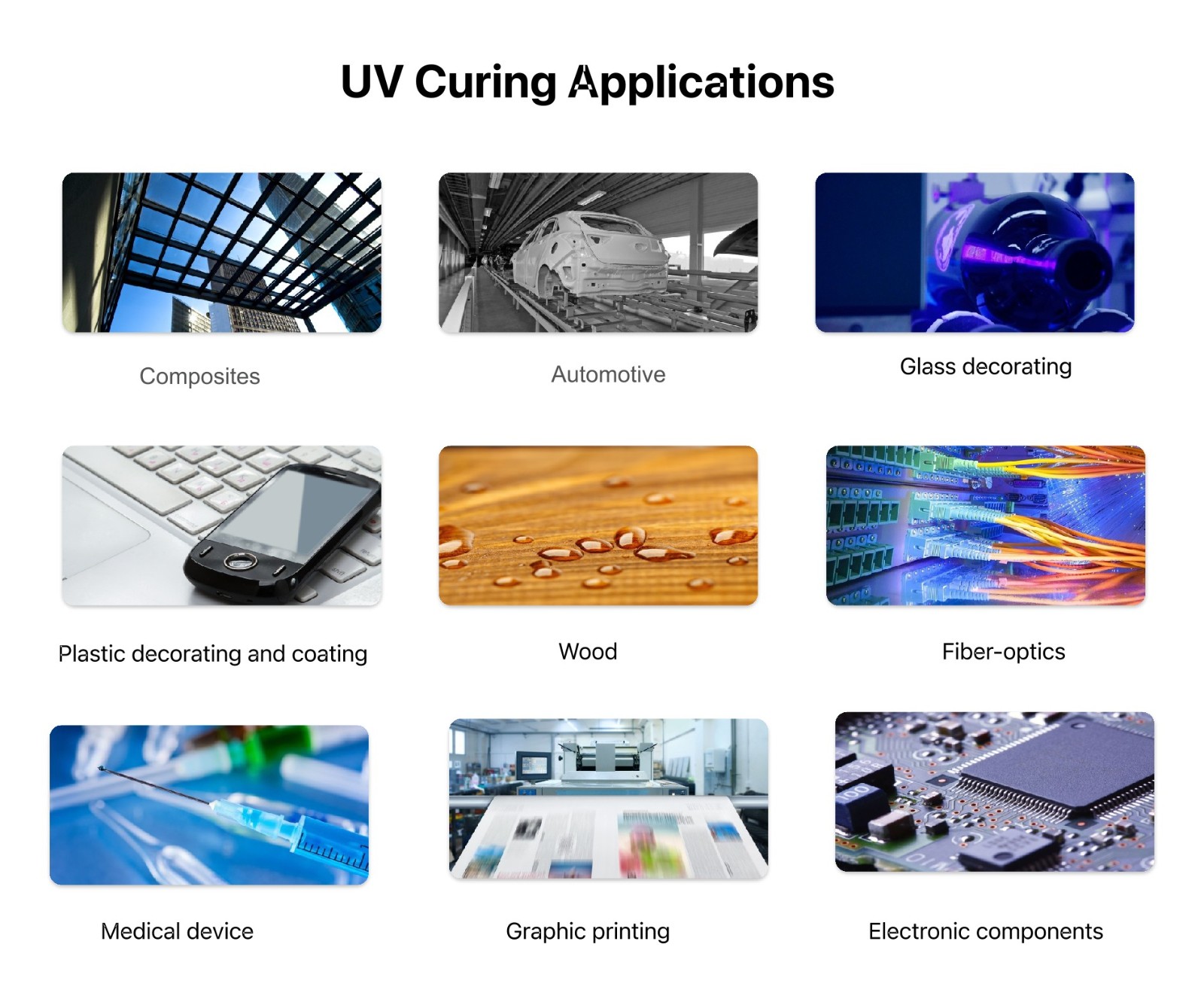

Applications for This Fast Dynamic Response UV Ballast and Power Supplies.

What Are The advantages of Drying and curing wood products coatings with UV technology?

Drying and curing wood products coatings with UV technology offer several advantages. UV technology provides a fast and efficient curing process, significantly reducing drying times compared to traditional methods. This results in increased production speed and throughput, allowing manufacturers to meet tight deadlines and improve overall efficiency. Additionally, UV curing produces a hard and durable finish on wood products, enhancing their resistance to wear, scratches, and chemicals. This helps to prolong the lifespan of the coated wood products and maintain their appearance over time. Furthermore, UV curing is an environmentally friendly option as it does not emit harmful volatile organic compounds (VOCs) during the curing process, making it a sustainable choice for wood coating applications.

How Can the Use of UV Technology for Drying and Curing Wood Coatings Help Manufacturers Reduce Costs and Increase Competitiveness in the Market?

The use of UV technology for drying and curing wood coatings can help manufacturers reduce costs and increase competitiveness in the market in several ways. Firstly, UV curing is a faster process compared to traditional methods, leading to increased production efficiency and throughput. This can result in lower energy consumption and labor costs, ultimately reducing overall production costs. Additionally, UV-cured coatings have a longer lifespan and require less maintenance, reducing the need for frequent recoating and touch-ups. This can lead to cost savings in the long run and improve the overall competitiveness of the wood products in the market. Furthermore, the environmentally friendly nature of UV curing, with its minimal emissions of VOCs, can help manufacturers meet regulatory requirements and appeal to environmentally conscious consumers, further enhancing their competitiveness.

What Are the Key Benefits of integrating Energy Detection Capabilities into UV Curing Systems?

Integrating energy detection capabilities into UV curing systems offers several key benefits. Firstly, it allows for precise monitoring and control of the light intensity, ensuring consistent and uniform curing results. This leads to improved product quality and reliability. Secondly, energy detection enables operators to optimize the curing process by adjusting parameters in real-time based on energy feedback, resulting in increased efficiency and reduced energy consumption. Additionally, the ability to detect and respond to fluctuations in energy levels enhances system safety and helps prevent potential issues that could impact the curing process.

How Does the Energy Detection Feature Enhance the Monitoring and Control of light intensity in UV Curing Systems??

The energy detection feature enhances the monitoring and control of light intensity in UV curing systems by providing real-time feedback on the amount of energy being delivered to the curing process. This allows for precise adjustments to be made to ensure optimal curing results and consistency in the final product. By monitoring energy levels, operators can also detect any fluctuations or abnormalities in the system, enabling timely intervention to prevent potential issues or defects in the curing process.